Significant volumes of hydrocarbons are found in naturally fractured reservoirs, especially in fields abandoned due to inadequate testing and assessment or because wells did not intersect fractures. Work in one may fail miserably in another. Consequently, each exploration site of a naturally fractured reservoir (NFR) should be considered as a research project by itself.

The article presents an overview of the problems associated with drilling in naturally fractured reservoirs (NFR), as well as the classification of naturally fractured reservoirs.

Keywords: hydrocarbon, drilling, naturally fractured reservoirs, matrix blocks, porosity, and permeability.

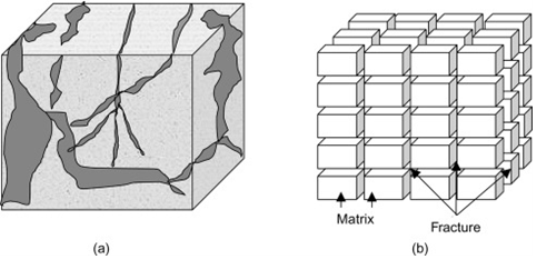

Formations that are naturally cracked vary from formations that aren't naturally cracked. They are heterogeneous in nature and comprise matrix blocks that are divided from one another by a fracture system, as seen in (fig.1).

Fig. 1. Fractured formations [14]

The initial rock that existed prior to fracture serves as the basis for matrix blocks. The permeability and porosity of the matrix define it. A fractured system is distinguished by its porosity and permeability. As a result, naturally broken water reservoirs are both porous and permeable.

To maximize oil field development, conventional drilling must minimize formation damage, especially in cracked carbonate formations that frequently have low matrix permeability.

Drilling fluid intrusion into cracked formations can result in serious formation damage all around wellbore, lower well productivity, and eventually lower field recovery rates.

Methods and materials. Therefore, with this kind of formation, it is crucial to limit solute absorption. Underbalanced drilling is the process of drilling when the formation pressure is kept lower than the drilling fluid pressure inside the well. Underbalanced drilling has been proven to increase productivity in the past. When used correctly, underbalanced drilling can greatly minimize or perhaps completely prevent the penetration of drilling mud into fractured systems. Although underbalanced drilling provides several positives over overbalanced drilling, it is crucial to accurately characterize the formation and estimate any potential formation damage via feasibility studies [1].

The literature reports several methods for analyzing the viability of unbalanced drilling. A model for estimating well production while taking near-well formation damage was provided by Ding et al. [2]. The reservoir damage analysis for horizontal wells in this model incorporates laboratory data on clay crust characteristics, polymer adsorption/retention, water blockage, etc. represents the impacts of the ensuing formation damage using relative permeability. In heterogeneous layers of the media, the model may be utilized to estimate layer damage. A relatively close formation damage model in asymmetrical settings was provided by Ding et al. [3]. Their subsequent work, which is crucial for horizontal wells.

For the balanced and unbalanced drilling instances, respectively, Leising and Rike [4] employed an analytical methodology to determine the productivity index (PI). Numerous clay crust components were used however the model didn't have any characteristics that would have represented the dynamic filtering procedure. As a function of drilling parameters and crack aperture, Lietard and Unwin [5] proposed an analytical equation to estimate the radius of absorbance in fractured reservoirs. The fundamental model reflects fluid flow through two parallel plates of constant width, and this equation is constrained by infinite fracture permeability. They arrived at the conclusion that an exact analytical is not feasible for a method with positive yield values after solving the problem numerically.

A method for reservoir damage analysis was proposed by Suryanarayan and colleagues [6] by adding a model calibrated based on the results of dynamic core flood tests into such a dynamic real setting. Built on the permeability data acquired from the laboratory investigation, the simulator, which is based on an ultrafine grid, provides an effective permeability pattern inside the absorption zone. This study only employed one porosity model and did not address the scenario of a broken reservoir.

Studying formation damage in broken formation assemblies was done by Salimi and Andersen [7]. To simulate the production increase mechanism with an imbalanced drilling operation, a dual porosity model with a Warren-Root configuration was taken into consideration. Studying collector criteria for choosing imbalanced drilling prospects was done by Xiong and Shan [8]. The economic advantages of underbalanced drilling operations were examined using an incremental net present value (NPV) model. They investigated the processes of productivity increase by underbalanced drilling using a numerical modeling technique that takes formation damage mechanisms into account.

A computational method for simulating potential formation damage while unbalanced drilling in homogenous reservoirs are reported by Ding et al [3]. In their research, they employed a two-phase flow modeling to demonstrate how underbalanced drilling might cause invasive formation damage. To mimic transient overbalanced time periods, they employed a model created for balanced drilling in prior research. Cracks and diverse reservoirs, however, were not covered in their work.

Results and discussion. Don't interfere with the well is a general rule that applies to naturally fractured formations. In another situation, something that appears to work may not. Because of this, every natural fractured reservoir being explored as well as every natural fractured reservoir already in used need to be seen as an exploratory project.

Geological classification.

According to geology, faults can be categorized as tectonic, regional, contractional (diagenetic), and surface-related faults, which are all connected to folding and/or faulting. Regional rifts, contractional faults, and tectonic faults have historically produced the majority of hydrocarbons. As far as overall hydrocarbon output from the surface is concerned, insignificant. Azimuth, dip, interval, and, if feasible, crack aperture must all be taken into account when categorizing cracks to establish the size and direction of in-situ primary stresses.

Classification of pores.

Based on Coalson et al [8]'s categorization of typical reservoir porosity types, preliminary estimations of productivity can be generated.

In this classification, pore shape and pore size serve as the primary determinants of porosity classes. The geometrical structure consists of:

Intergranular, inter-crystalline, lattices, and fractures are typical types of pores. Any of these when combined can result in dualism and even more permeable behavior.

Winland [9] and

Mega-porosity is defined as

Mega-pores can move tens of thousands of barrels per day, whereas macro-pores can move thousands of barrels per day, meso-pores can move hundreds of barrels per day, and micro-pores can move tens of barrels per day, according to Martin et al [11].

Classification of hydrocarbon resources.

Cracked layers fall into one of three categories: A, B, or C from the perspective of storage. Because many reservoirs naturally occurs fractures which would otherwise be unproductive, it is commercial.

The majority of the hydrocarbon reserve in A-type formations is found in the matrix porosity, with a smaller fraction found in the cracks. Natural cracks often have more permeability than the matrix, which typically has extremely low permeability. Though there are few outliers. For instance, the massive Ghawar reservoir in Saudi Arabia features a matrix with extremely large pores and high permeability. On the one hand, cracks in these types of collectors are undesirable since they make it easier for undesired water to flow. For instance, rather than cutting faults, efforts are concentrated on integrating geology information, 3D seismic data, and pressure changes analysis.

The hydrocarbon reserves in B-type rocks are split around 50/50 between porosity and fractures. Despite the matrix's density, it is more porous than fissures.

There are no hydrocarbon reserves in the porosity-free C-type deposits; all of them are found in fractures. So, in this instance, the fractures offer the storage and permeability required to accomplish commercial production.

There are several reservoirs with tectonic cracks where the principal porosity (matrix) tendency to be blocked or has incredibly poor permeability and does not sustain any hydrocarbon reserves. In these situations, there could be a lot of micro-cracks acting as «matrix» porosity. This is because there are many different types of tectonic faults, ranging in size from the largest to the smallest grains. Multiple porosity activity in this instance may result from the interaction of micro and macro cracks.

Conclusion. A wide and continuous fracture network, which has a significant impact on the formations, is the reason why wells in naturally fractured formations have a high productivity. Since fracture porosity makes up a tiny portion of the overall rock porosity in naturally fractured rocks, the absorption radius is high. The majority of drilling fluid absorption there takes place in the cracks. Consequently, drilling fluid solids that fill natural cracks might lower output. Minimizing liquid penetration in this kind of collection is crucial, for this reason. Underbalanced drilling has been proven to increase production, as is common knowledge in the field. When done properly, underbalanced drilling can greatly limit or perhaps completely prevent the penetration of drilling mud into crack systems [12]. Unbalanced drilling offers a few benefits over balanced drilling, but before using unbalanced drilling, it is necessary to understand the possible harm it might cause.

Two primary issues during unbalanced drilling might significantly harm the wellbore [13]:

- A momentary condition of equilibrium.

- Absorption across capillaries.

For numerous causes, including breakdown procedures or pipe connections, an overbalanced pressure may be given to the formation for a brief length of time in the first damage category. Drilling fluid and highly filtered fluid can enter and develop in the fracture system in the absence of an exterior protective clay crust, lowering fracture permeability. By phase trapped in the rock matrix and water sorption in the vicinity of the wellbore and material trapping in the fracture, the drilling fluid can alter the relative permeability.

In situations where capillary force is crucial, countercurrent imbibition happens when the formation fluid moves down the wellbore and the clay crust penetrate the formation. Because the fractures in this type of formation have a wide spacing between them, the suction effect is less of a problem when drilling a well in one.

References:

- Bennion, D. B. Underbalanced Drilling of Horizontal Wells—Does it Really Eliminate Formation Damage. In Proceedings of Formation Damage Symposium, Lafayette, LA, USA, 7–10 February 1994.

- Ding, Y.; Longeron, D.; Renard,G.; Audibert, A. Modeling of Both Near-Wellbore Damage and Natural Cleanup of Horizontal Wells Drilled With a Water-Based Mud. In Proceedings of SPE Int.Symp.& Exhibition on Formation Damage Control, Lafayette, LA, USA, 20–21 February 2002.

- Ding, Y.; Herzhaft, B.; Renard, G. Near-wellbore Damage Effects on Well Performance-A Comparison Between Underbalanced and Overbalanced Drilling. In Proceedings of The SPE Symp. & Exhibition on Formation Damage Control, Lafayette, LA, USA, 18–20 February 2004:

- Leising, L.J.; Rike, E. A. Underbalanced Drilling With Coiled Tubing and Well Productivity. In Proceedings of The SPE European Petroleum Conference, London, UK, 25–27 October 1994.

- Lietard, O.; Unwin, T.; Guillot, D.; Hodder, M. Fracture Width LWD and Drilling Mud/LCM Selection Guidelines in Naturally Fractured Reservoirs. In Proceedings of European Petroleum Conference, Milan, Italy, 22–24 October 1996.

- Suryanarayan, S.V.; Wu, Zh.; Ramalho, J.; Himes, R. Dynamic modeling of invasion damage and impact on production in horizontal wells. SPE Reservoir Eval. Eng. 2007, 10, 348–358.

- Salimi, S.; Andersen, K. I. Enhancement Well Productivity-Investigating the Feasibility of UBD for Minimizing Formation Damage in Naturally Fractured Carbonate Reservoirs. In Proceedings of SPE/IADC Underbalanced Technology Conference and Exhibition, Houston, TX, USA, 11–12 October 2004.

- Xiong, H.; Shan,D. Reservoir Criteria for selecting Underbalanced Drilling Candidates. In Proceedings of Underbalanced Technology Conference, Houston, TX, USA, 25–26 March 2003.

- Coalson, E. B., Hartmann, D. J., and Thomas, J. B.: Productive Characteristics of Common Reservoir Porosity Types, Bulletin of the South Texas Geological Society, v. 15, No. 6 (February 1985), pp. 35–51.

- Aguilera, R.: Incorporating Capillary Pressure, Pore Throat Aperture Radii, Height Above Free Water Table, and Winland R35 Values on Pickett Plots, AAPG Bulletin, v. 86, no. 4 (April 2002), p. 605–624.

- Martın,A.J. et al: Characterization of Petrophysical Flow Units in Carbonate Reservoirs, AAPG Güllərin, v.83, no. 7 (May 1997), p.734–759.

- Bennion, D.B.; Thomas, F. B. Underbalanced Drilling a Reservoir Design Prespective. In Proceedings of Horizontal Well Technology, Calgary, Canada, 3 November 1999.

- Bennion, D.B.; Thomas, F.B.; Bietz, R.F.; Bennion, D. W. Underbalanced Drilling, Praises and Perils: Lab and Field Experience. In Proceedings of Horizontal Well Technology, Calgary, Canada, 21 November 1995.

- https://www.sciencedirect.com/topics/engineering/naturally-fractured-reservoir.