Gypsum-based materials are widely used in the construction industry due to their properties of resistance to moisture changes, ability to take shape, rapid curing properties, fire resistance, etc. The use of waste materials as raw materials in the production of gypsum based materials is an economical alternative to conventional production methods and also reduces the amount of waste. This paper discusses the possibility of utilizing gypsum and waste materials for the manufacture of building products. In this context, many studies have been carried out on new composites, in particular on the mechanical (flexural strength, compressive strength, surface hardness), physical (density) and thermal properties of gypsum, aimed at improving the environmental performance of traditional materials used in construction. The paper gives an overview of the mechanical and physical characteristics of gypsum composites with added wastes and investigates the effect of adding different types of wastes in different amounts.

Keywords : gypsum, plaster, gypsum composition, wastes, waste materials.

1. Introduction

Since ancient times, gypsum has served as a fundamental building material, with early instances traced back to a city in Asia Minor around 9000 BC, where gypsum plaster formed the foundation for ornamental tiles. As the mid-19th century approached, distinctions arose between semi-hydrate and anhydrite plasters, paralleled by advancements in understanding the interplay between processing techniques and manufacturing temperatures. This era saw the emergence of various applications for gypsum, including its use in mortar and floor screed production. Throughout the 20th century, the significance of plastering escalated, coinciding with the innovation and proliferation of gypsum-based products such as gypsum panels, gypsum boards, and gypscarton. Subsequent developments included the introduction of machine-applied plaster mortars and the advent of self-leveling floor screeds formulated from anhydrite and α-hemihydrate [1].

The operations of numerous enterprises lead to the accumulation of diverse wastes. Certain types of industrial waste exhibit chemical compositions and properties akin to, or in some cases, superior to those of natural raw materials commonly employed in the building materials industry. This similarity or superiority enables their utilization as cost-effective substitutes in manufacturing processes [2].

Gypsum is one of the most environmentally friendly materials. Consequently, ongoing efforts involve the development and evaluation of novel gypsum-based materials, alongside the exploration of new potential applications. In this pursuit, the strategy of incorporating waste materials into gypsum shows significant promise.

2. Materials and methods

To achieve the goals of the study, a search was conducted for articles published over the past decade. Among them, the main attention was paid to the research of gypsum composites with construction or other industrial waste and their use in construction.

The search was conducted mainly in journals included in the Elsevier platform, namely in the journal Construction and Building Materials, Journal of Materials Research and Technology, Journal of Building Engineering, Waste Management. In addition, a selection of scientific articles from the Google Scholar search engine was made. A search was also conducted using data from publishers such as IOP Publishing on the ResearchGate scientific platform.

3. Results

Many studies have been found on the use of construction and demolition waste to replace components of gypsum compositions. A summary of the studies of gypsum composites with the addition of waste is presented in Table 1.

Table 1

Summary of research on gypsum composites with added waste

|

Author |

Added waste |

Studied properties |

|

Gutiérrez-González S. et al. [3] |

Polyurethane foam waste |

Mechanical, physical properties, thermal condition |

|

del Rio Merino M. et al. [4] |

Polystyrene waste |

Mechanical and physical properties |

|

Laoubi H. et al. [5] |

Polystyrene waste |

Mechanical and physical properties |

|

San-Antonio-González A. et al. [6] |

Extruded polystyrene waste |

Mechanical, physical properties, thermal condition |

|

Sáez P. et al. [7] |

Expanded polystyrene, ceramics and concrete wastes |

Mechanical and physical properties |

|

Romaniega Piñeiro S. et al. [8] |

Mineral wool fibers waste |

Mechanical and physical properties |

|

Durgun M. Y. [9] |

Roofing tile powder waste |

Mechanical, physical properties, thermal condition |

|

Gutiérrez-González S., Gadea J. et al. [10] |

Polyamide powder waste |

Mechanical, physical properties, thermal condition |

3.1 Adding waste to reduce gypsum density

S. Gutiérrez-González et al. [3] investigated the use of polyurethane foam waste to produce a lightweight gypsum material with improved thermal properties. The results show that an increase in the amount of polyurethane reduces the density and mechanical properties of the plaster, at the same time its thermal resistance increases in proportion to the decrease in density. These results show that plaster with polyurethane foam residues can be equated to plaster lightened with conventional materials.

M. del Rio Merino et al. [4] used polystyrene waste to make lightweight plaster and determined its physical and mechanical properties. Two types of polystyrene were used in the samples developed for testing: expanded polystyrene (EPS) and extruded polystyrene (XPS). The addition of EPS or XPS residues to gypsum made it possible to reduce the density to 35.35 % compared to samples without additives and achieve mechanical strength above the requirements established by regulatory documents for light gypsum.

H. Laoubi et al. [5] created a gypsum composite using waste polystyrene and dune sand as fillers. The gradual addition of EPS (from 0 to 50 %) to the matrix consisting of gypsum and bottom sand led to a decrease in density from 27.15 % to 56.7 % (613 and 1414 kg/m 3 ). Due to the proportion of polystyrene introduced, a decrease in mechanical strength was recorded, a decrease in compression by about 77.30 %.

A. San-Antonio-González et al. [6] investigated the use of waste extruded polystyrene for the manufacture of simplified plaster. The researchers concluded that the properties of the prepared formulations depend on the size of the added XPS particles. The addition of XPS fillers in an amount of 4 % reduces the density of plaster to 20 %, reduces the absorption of capillary water by about 30 % and improves thermal properties (reduces thermal conductivity to 37.6 %).

3.2 Adding waste to improve the mechanical properties of gypsum

S. Romaniega Piñeiro et al. [8] added waste mineral wool, rock wool and fiberglass to the gypsum matrix. Their results showed an increase in density (6 %), Shore surface stiffness (10 %) and bending strength (25–35 %). But the compressive strength was reduced (12–35 %), although the values corresponded to the limits specified in regulatory documents.

The use of polystyrene, ceramic and concrete waste from construction and demolition waste in a gypsum matrix was studied by P. Sáez et al. [7]. The results showed that the addition of ceramic and concrete waste improves mechanical performance. In particular, the addition of ceramic waste up to 75 % by weight of gypsum increases the mechanical strength and density of gypsum without additives. The addition of styrofoam waste reduces their density and reduces capillary absorption of water. In general, these compounds provide significant advantages, since the mechanical and thermal characteristics are improved compared to traditional plasters, and the consumption of raw materials is reduced.

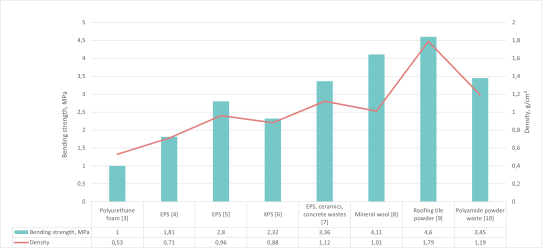

The main results obtained in the analyzed studies (bending strength, compressive strength, density) are shown in Figures 1–2, respectively.

Fig. 1. The results of determining the density and bending strength of gypsum composites with the addition of waste

Fig. 2. The results of determining the density and compressive strength of gypsum composites with the addition of waste

3.3 High-temperature investigation of gypsum properties with the addition of waste

M. Y. Durgun [9] added recycled roofing tile powder as waste to gypsum-based mixtures and studied its properties at ambient temperatures and at 600°C-800°C temperatures. The results showed that when the recycled tile powder was added, the strength of the mixtures decreased, porosity and water absorption increased. However, recycled tile powder increases weight loss, thermal conductivity and resistance to high temperatures.

Gutiérrez-González S., Gadea J. et al. [10] investigated the compatibility of gypsum residues and polyamide powder. The results showed that an increase in the proportion of polyamide led to a decrease in density and mechanical properties, but increased heat resistance. It has been found that this polyamide can withstand high temperatures from 380 to 580°C without breaking. The conclusion of the study indicates that the remnants of polyamide powder can be used to create a new type of lightweight plaster with improved thermal properties.

4. Conclusion

The use of waste in the production of gypsum materials is a promising solution in the context of supporting sustainable development. This approach is becoming a key focus in the industry, given the increased focus on sustainability and environmental protection. However, there are a number of challenges, such as the development of cost-effective processes, the selection of acceptable waste, and the establishment of quality and safety standards. Many studies demonstrate that waste can successfully replace natural fillers in the production of gypsum materials. It was determined that in recent years, researchers have begun to actively create building products from gypsum and waste, opening up new prospects in this field.

References:

- Singh M. Gypsum & Gypsum Products: Their Science & Technology. — Taylor & Francis, 2022.

- Дергунов С., Орехов С. Сухие строительные смеси (состав, технология, свойства). — Оренбург, 2012.

- Gutiérrez-González S., Gadea J., Rodríguez A., Junco C., Calderón V. Lightweight plaster materials with enhanced thermal properties made with polyurethane foam wastes. — Construction and Building Materials, 2012. https://doi.org/10.1016/j. conbuildmat.2011.10.055

- del Rio Merino M., Villoria Sáez P., Longobardi I., Santa Cruz Astorqui J., Porras-Amores C. Redesigning lightweight gypsum with mixes of polystyrene waste from construction and demolition waste. — Journal of Cleaner Production, 2019. https://doi. org/10.1016/j.jclepro.2019.02.132

- Laoubi H., Bederina M., Djoudi A., Goullieux A., Dheilly R. M., Queneudec M. Study of a New Plaster Composite Based on Dune Sand and Expanded Polystyrene as Aggregates. — The Open Civil Engineering Journal, 2018. https://doi.org/10.2174/18741495018 12010401

- San-Antonio-González A., Del Río Merino M., Viñas Arrebola C., Villoria-Sáez P. Lightweight material made with gypsum and extruded polystyrene waste with enhanced thermal behaviour. — Construction and Building Materials, 2015. https://doi.org/10.1016/j.conbuildmat.2015.05.040

- Sáez P., del Río Merino M., Sorrentino M., Porras-Amores C., Astorqui J., Viñas C. Mechanical Characterization of Gypsum Composites Containing Inert and Insulation Materials from Construction and Demolition Waste and Further Application as A Gypsum Block. — Materials, 2020. https://doi.org/10.3390/ ma13010193

- Romaniega Piñeiro S., del Río Merino M., Pérez García C. New Plaster Composite with Mineral Wool Fibres from CDW Recycling. — Advances in Materials Science and Engineering, 2015. https://doi.org/10.1155/2015/854192

- Durgun M. Y. Experimental research on gypsum-based mixtures containing recycled roofing tile powder at ambient and high temperatures. — Construction and Building Materials, 2021. https://doi.org/10.1016/j.conbuildmat. 2021.122956

- Gutiérrez-González S., Gadea J., Rodríguez A., Blanco-Varela M. T., Calderón V. Compatibility between gypsum and polyamide powder waste to produce lightweight plaster with enhanced thermal properties. — Construction and Building Materials, 2012. https://doi.org/10.1016/j.conbuildmat.2012.02.061