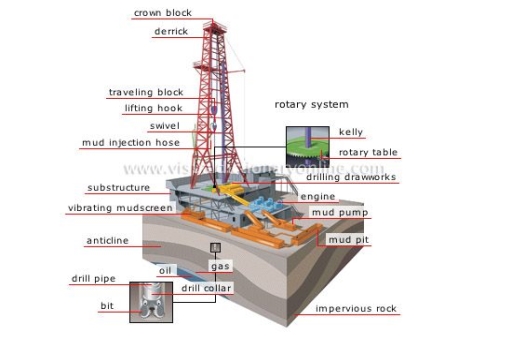

Fig. 1. Drilling Rigs | Tidal Petroleum

Overview of the Well Construction Process

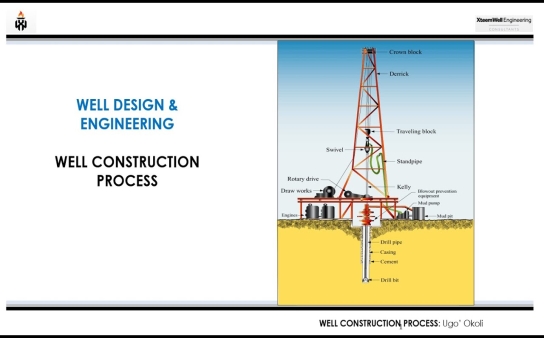

The well construction process begins with geological surveys and site selection, followed by rig mobilization. Once on-site, the drilling phase commences with the spudding of the well inserting the initial conductor pipe. Subsequent steps include drilling the surface hole, installing casing strings, and cementing to secure the wellbore integrity. In deeper sections, intermediate and production casings are added as the drill advances through various formations. The process relies on mud circulation to cool the bit, remove cuttings, and maintain pressure balance. Completion involves perforating the casing and installing production tubing. Throughout, monitoring tools like logging-while-drilling (LWD) provide real-time data on formation properties. Diagrams of this process often depict sequential stages, from rig setup to final testing. For instance, a flowchart might show the progression from exploration to abandonment if necessary. In our project example, the well was designed with a 12–1/4-inch surface hole, followed by 8–1/2-inch intermediate drilling, using water-based mud initially and switching to oil-based for stability in reactive shales. Potential incidents can occur at any stage, but they are most prevalent during drilling due to high mechanical stresses and unpredictable subsurface conditions.

Fig. 2. Oil Well Construction Process Land Operations

Drilling Tools Used in the Project

Drilling tools form the backbone of well construction, each designed for specific functions. Key components include the drill bit (e.g., polycrystalline diamond compact or PDC bits for hard rock), drill pipe (tubular steel sections connecting the bit to the surface), bottom-hole assembly (BHA) with stabilizers and reamers, and the top drive or Kelly for rotation. In oil and gas operations, tools like mud motors enable directional drilling, while blowout preventers (BOPs) serve as critical safety barriers. Our project utilized a 6–5/8-inch drill pipe with API premium connections, a PDC bit for efficiency in sandstone layers, and a ram-type BOP stack rated for 10,000 psi. These tools must withstand extreme pressures, temperatures, and corrosive environments. Visual inspections and maintenance are routine, but failures can still arise from material fatigue or improper handling.

Fig.3. Different Types of Drilling Bits in Oil and Gas Industry...

Tools are selected based on formation analysis; for example, roller cone bits might be used in softer formations to reduce torque issues. In this project, the BHA included measurement-while-drilling (MWD) tools for real-time telemetry, enhancing precision but adding complexity that could contribute to incidents if not managed properly.

Common Drilling Tool Incidents Drilling tool incidents

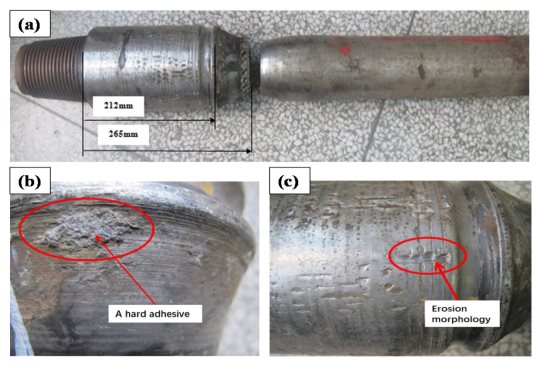

Manifest in various forms, such as bit balling (cuttings adhering to the bit), pipe sticking (drill string immobilized by differential pressure), twist-offs (pipe fracturing under torque), or blowouts (uncontrolled fluid release). In the oil and gas sector, blowouts are particularly severe, often resulting from kick events where formation fluids enter the wellbore. In our hypothetical project, an incident occurred at 2,500 meters when the drill pipe twisted off due to excessive torque in a faulted zone. Another common issue is tool washout, where erosion from abrasive mud leads to leaks. Statistics show that equipment failure and human error account for the majority of blowouts, primarily during drilling and completion. Images of failed tools often reveal cracks, corrosion, or deformation, underscoring the need for robust design and monitoring.

Fig. 4. Failure Analysis of Drill Pipe during Working Process in a Deep...

Severe incidents, like those in tight shale plays, can involve mud losses or pressure surges, as seen in cases where diesel-based mud failed to maintain stability.

Analysis of Causes — Human Factors

Human factors are implicated in over 80 % of drilling incidents, encompassing errors in decision-making, inadequate training, or procedural non-compliance. In the oil and gas industry, fatigue from long shifts, poor communication, or overriding safety protocols can lead to catastrophic failures. A detailed analysis using the Human Factors Analysis and Classification System (HFACS) reveals patterns like unsafe acts (e.g., improper torque application) stemming from organizational influences (e.g., cost-cutting on training). In our project, a human error in mud weight calculation contributed to a kick, exacerbating tool stress. Negligent practices, such as skipping pre-job inspections, amplify risks. Case studies show that inadequate training often results in pressure imbalances, leading to blowouts. Addressing these requires behavioral safety programs and simulation training.

Analysis of Causes — Equipment and Environmental Factors

Beyond human elements, equipment failures arise from material defects, wear, or design flaws. Large-size drilling tools, like heavy-weight drill pipes, fail due to fatigue cracks or corrosion in harsh environments. Environmental factors, such as unstable formations or high temperatures, accelerate degradation. In deep wells, kicks from underbalanced drilling are common root causes of blowouts. Our project experienced tool failure from abrasive sands eroding the bit prematurely. Statistical analyses highlight that blowouts often result from combined equipment and human errors during operations. Technical measures, like using premium alloys, mitigate these, but unpredictable geology remains a challenge.

Fig. 5. How To Identify Drill Bit Failure While Drilling an Oil Well

Conclusion

Implement root cause analysis post-event, enhance tool inspections, and adopt real-time monitoring technologies. Best practices include blowout prevention plans, regular audits, and crew competency assessments. In conclusion, while well construction projects drive energy production, understanding drilling tool incident causes primarily human, equipment, and environmental is crucial for safety and efficiency. This analysis underscores the need for integrated risk management in the industry. By applying these insights, future projects can minimize disruptions and promote sustainable operations.

References:

- Occupational Safety and Health Administration. (n.d.). eTool: Oil and Gas Well Drilling and Servicing — General Safety — Common Wellsite Incidents and Fatalities. https://www.osha.gov/etools/oil-and-gas/general-safety/common-wellsite-incidents

- PetroSync. (2025, August 31). 11 Common Drilling Challenges and How to Solve Them. https://www.petrosync.com/blog/drilling-challenges/

- Liu, Y., et al. (2022). The failure patterns and analysis process of drill pipes in oil and gas well: A case study of fracture S135 drill pipe. ScienceDirect. https://www.sciencedirect.com/science/article/abs/pii/S1350630722001455

- Occupational Safety and Health Administration. (n.d.). Oil and Gas Extraction — Hazards. https://www.osha.gov/oil-and-gas-extraction/hazards

- Quora. (n.d.). What are some of the reasons for failure in drilling wells for oil & gas exploration?. https://www.quora.com/What-are-some-of-the-reasons-for-failure-in-drilling-wells-for-oil-gas-exploration

- IntechOpen. (2023, September 25). Drilling of Wells That Provoked Natural and Man-Made Disasters. https://www.intechopen.com/chapters/87617