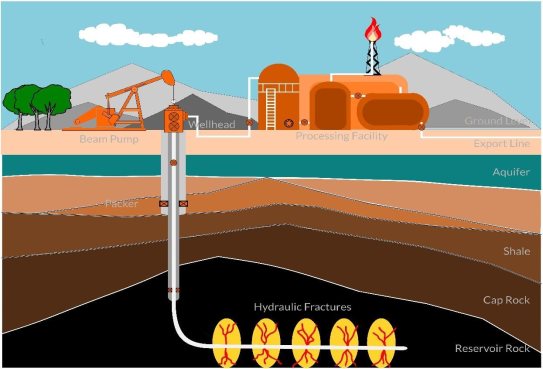

Fig. 1. Everything You Need to Know About Oilwell Drilling — Borregaard

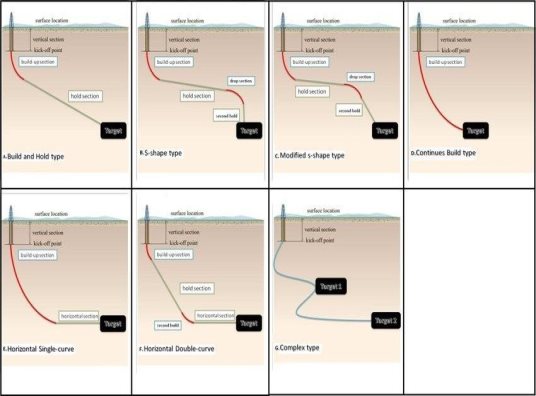

Horizontal drilling illustrations highlight the transition from vertical to lateral sections, where DLS is most pronounced during the curve-building phase.

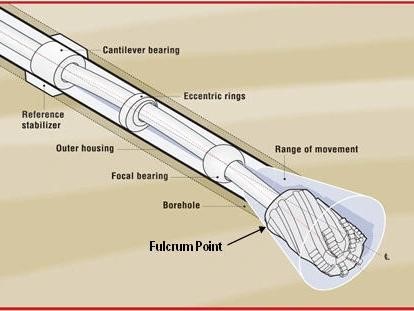

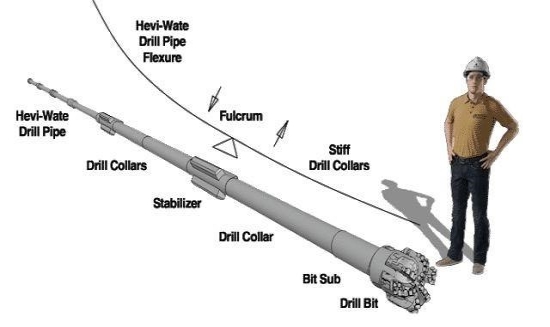

Understanding Bottom Hole Assembly (BHA)

Understanding Bottom Hole Assembly (BHA) The BHA is essential for directing the drill bit and maintaining wellbore stability. Key components include the drill bit for cutting rock, drill collars for providing weight on bit (WOB), stabilizers to centralize the assembly and control deviation, and specialized tools like mud motors or rotary steerable systems (RSS) for directional control. In horizontal drilling, the BHA must be robust enough to handle high torsional loads while allowing precise trajectory adjustments. Optimization of BHA involves selecting components based on factors such as well profile, formation characteristics, and desired build rates. For example, in complex well profiles, combining BHA with fixed cutter drill bits and flow-activated friction reduction tools has shown promise in enhancing directional performance.

Fig. 2. Bottom Hole Assembly: What It Is and Its Uses — Rock Drilling Tool...

This integrated approach reduces friction and improves weight transfer, crucial for managing DLS in extended-reach horizontals. A typical BHA diagram illustrates the arrangement of components, from the bit at the bottom to connectors linking to the drill string. Common BHA types for horizontal drilling include pendulum assemblies for natural drop tendencies, packed-hole assemblies for stability, and fulcrum assemblies for building inclination. Selecting the right type minimizes unintended doglegs and ensures the well stays on plan.

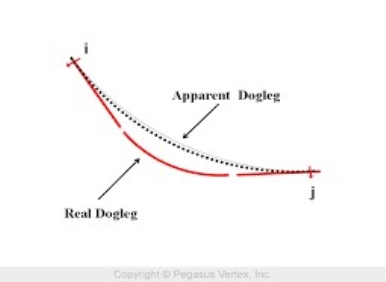

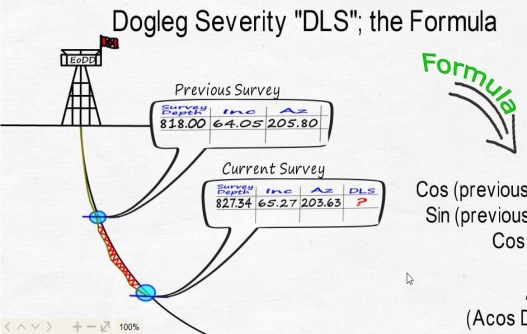

What is Dogleg Severity (DLS)?

Dogleg severity is quantified as the change in wellbore direction per unit length, typically measured in degrees per 100 feet (or 30 meters). It is calculated using survey data from inclination and azimuth measurements at successive points along the wellbore. The formula for DLS is derived from the curvature of the trajectory, often using the minimum curvature method for accuracy. High DLS can cause excessive bending stresses on the drill string, leading to fatigue failure in components like drill pipe or casing. In horizontal sections, maintaining low DLS is vital to prevent keyseating, where the pipe wears a groove in the wellbore wall. Research shows that DLS should be controlled inversely proportional to drilling drag in horizontal wells to optimize friction management.

Fig. 3. Casing Wear Series 12: Dogleg Severity | Pegasus Vertex, Inc. Blog

Diagrams of dogleg severity often depict the angular change over distance, highlighting real versus apparent doglegs in 3D space. Methods for mod eling DLS include inputting tool parameters and loads into simulation software to predict borehole curvature. These models help forecast potential issues before drilling commences.

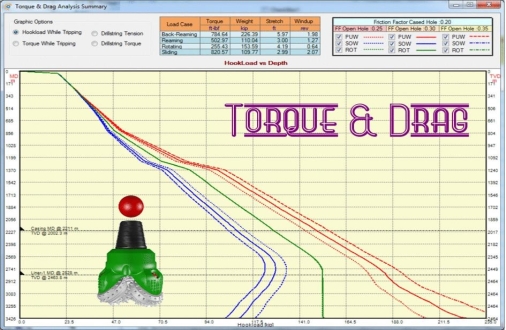

Challenges in Horizontal Drilling Related to DLS

Horizontal drilling operations face several challenges exacerbated by poor DLS management. These include increased torque and drag, which hinder weight transfer to the bit and elevate the risk of buckling. In extended-reach wells, high DLS amplifies friction, potentially leading to stuck pipe or reduced rate of penetration (ROP). Wellbore tortuosity, a direct result of varying DLS, affects completion operations by making it difficult to run casing or install production equipment. Studies in basins like the Eagle Ford and Permian have shown that conventional motor BHAs with high bend angles (>2 degrees) often produce build rates exceeding planned DLS, resulting in tortuous wellbores. Conversely, lower bend angles with added stabilizers promote smoother trajectories.

Fig. 4. Understanding Torque & Drag: Concepts and Analysis

Illustrations of torque and drag show forces acting on the drill string elements, emphasizing how DLS contributes to these stresses. Additionally, formation heterogeneity can induce unplanned doglegs, requiring real-time BHA adjustments. Particle swarm optimization algorithms have been applied to minimize DLS in directional wells by optimizing well patterns and measured depths.

Optimization Techniques for BHA in DLS Management

Optimizing BHA for DLS involves iterative modeling and field testing. One effective method uses static finite element analysis to simulate BHA interactions with the borehole, evaluating steering gain and bias across configurations. This approach normalizes performance metrics to select BHAs with optimal mechanical characteristics for specific inclinations. Integrated designs incorporating anti-deviation and vibration reduction features, such as multiple stabilizers and lower bend motors, have proven effective in maintaining verticality and reducing DLS in deviated sections. For horizontal laterals, pendulum BHAs optimized for maximum WOB help control drop tendencies.

Fig. 5. Dogleg Severity; the Formula (longhand), know your basics...

Techniques for DLS management are visualized through formulas and scenarios, like controlling build rates proportionally to drag. Advanced tools like RSS allow precise control without sliding, reducing tortuosity. Validation through slide ratios and surveys ensures BHA selections align with dogleg requirements.

Case Studies and Practical Applications

In a study on rotary steerable BHAs, configurations were tested at inclinations of 10°, 45°, and 80°, revealing that certain diameters (e.g., 6.75-in. to 11-in.) maximize steering gain while minimizing bias. This led to improved drilling success in horizontal operations. Another case in complex wells demonstrated that flow-activated friction reduction tools combined with optimized BHAs reduced drag and enhanced trajectory control. In US land drilling, shifting to lower-bend BHAs with stabilizers decreased tortuosity and improved wellbore quality in high-DLS-prone basins.

Fig. 6. Directional Drilling well types | Download Scientific Diagram

Well trajectory profiles in horizontal drilling showcase optimized paths with controlled DLS curves. Path optimization advisors using analytical tools account for BHA tendencies in slide drilling, assuming constant tool face for ideal trajectories.

Conclusion and Best Practices

Effective BHA optimization is key to managing DLS in horizontal drilling, ensuring safer and more efficient operations. By leveraging modeling techniques, selecting appropriate components, and validating through field data, operators can mitigate risks associated with high curvature. Best practices include using finite element simulations for pre-drill planning, incorporating stabilizers for stability, and employing RSS for precise control. Continuous monitoring with real-time data allows adjustments to maintain low DLS. Future advancements may integrate AI-driven optimization for even better outcomes.

Fig. 7. A Dive into the Bottom Hole Assembly (BHA) in Oil and Gas Drilling

Detailed BHA component breakdowns aid in visualizing optimized assemblies for DLS management.

References:

- Chen, Y., et al. (2023). «Influence of Wellbore Dogleg Severity on Drilling Friction in Horizontal Wells». Geofluids, Wiley Online Library. https://onlinelibrary.wiley.com/doi/10.1155/2023/9973863 (Discusses the impact of DLS on friction and recommendations for control in horizontal wells.)

- Janwadkar, S., et al. (2011). «Overcoming Challenges for Drilling HighDogleg-Severity Curves». SPE/IADC Drilling Conference and Exhibition, One Petro. https://onepetro.org/SPEDC/proceedings-abstract/11DC/11DC/149335 (Explores high-DLS curves with rotary steerable systems and single BHA solutions.)

- Hussain, S., et al. (2023). «Optimizing Directional Drilling by Enhancing Bottom Hole Assembly Design in Complex Well Profiles». Middle East Oil, Gas and Geosciences Show, OnePetro. https://onepetro.org/SPEMEOS/proceedings/23MEOS/23MEOS/D032S122R004/51 7506 (Focuses on integrated BHA designs with friction reduction tools for better trajectory control.)

- Mills, K.A., et al. (2016). «Micro Dogleg Detection with Continuous Inclination Measurements and Advanced BHA Modeling». Helmerich & Payne Technical Publication. https://www.helmerichpayne.com/resources/technicalpublications/micro-dogleg-detection-with-continuous-inclination-measurementsand-advanced-bha-modeling (Uses trajectory prediction models to estimate microdoglegs and optimize BHAs.)

- Menand, S., et al. (2015). «Selection of Optimum Bottom Hole Assembly Configuration Using Steering Prediction Modeling». Journal of Petroleum Science and Engineering. https://www.sciencedirect.com/science/article/abs/pii/S1875510015301530 (Describes numerical modeling for optimal BHA selection in rotary steerable systems, including finite element analysis for DLS prediction.)

- Noel, A., et al. (2023). «New One BHA Solution for High Dogleg Severity Curve and Lateral Drilling». SPE/IADC Drilling Conference and Exhibition, OnePetro. https://onepetro.org/SPEDC/proceedings-abstract/23DC/323DC/D031S022R001/516787 (Case study on single BHA for high-DLS curves and long laterals in the Permian Basin.)

- Drilling Manual. (2024). «Dogleg Severity Guide, Calculation & Formula». https://www.drillingmanual.com/dogleg-severity-guide-calculation-formula/ (Practical guide to DLS consequences, calculations, and effects on BHA.)