The economic importance of the problem of the use of oil resources, which ends in the construction of road pavements and roadway structures, reveals to us the relevance of developing materials with a large reserve of mineral resources [3].

In our country, the use of basalt fiber, which has a large reserve resource, in construction is becoming more and more widespread, the main reason for this is that, unlike metal fiber, it is not subject to electrochemical corrosion, and its use prevents the formation of corrosion in the structure and aggressive environments (sea water, chemical production exhaust, de-icing agents, etc.) has properties such as reducing the development of breakdowns [3].

Taking into account that we live in the conditions of a market economy, in this section, the economic efficiency that can be achieved by using KMB in the constructions of the road section is determined.

In this process, existing and proposed constructions of roadway structures of reinforced concrete highway bridges are economically compared.

Accounts are calculated according to the prices approved by the Ministry of Construction on a quarterly basis, based on the estimate made on the basis of the ABC 4 program.

Calculation work is considered for 1 m 2 of road constructions (a specific object is not taken for accounting work.

Estimates for 1m 2 of existing and proposed constructions were carried out in the ABC-4 program.

Table 1 shows labor costs for both options

Table 1

|

Labor cost |

For existing construction |

For the proposed construction |

|

man-hour |

0.81 |

0.17 |

|

machine-hour |

0.31 |

0.03 |

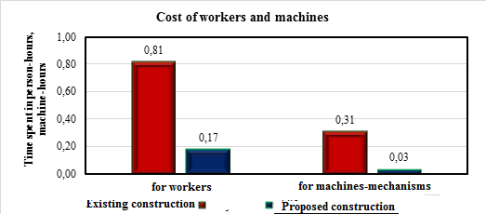

Fig. 1. Labor costs for workers and machines

As can be seen from the graph in Fig. 1, it is possible to save the labor costs of workers by 79 %, and the labor costs of machines and mechanisms by 90 % compared to the existing method.

The amount of expenses for labor costs is presented in table 2.

Table 2

|

Existing construction |

Proposed construction | |

|

for workers |

12341.22 |

2461.87 |

|

for machines-mechanisms |

3580.54 |

2539.18 |

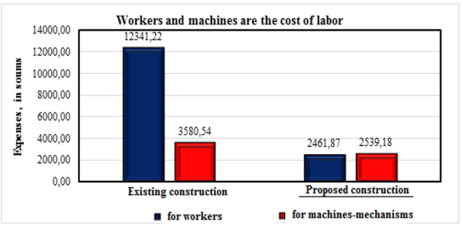

Fig. 2. Cost graph for workers and machinery

From the above graphic data, we can see that the cost of the machines and mechanisms of the proposed method is 30 % cheaper than the existing method, and that of the workers is 80 % cheaper.

Material consumption of constructions is given in table 3.

Table 3

|

Existing construction |

Proposed construction | |

|

Costs for construction material, soum |

125569.80 |

134139.13 |

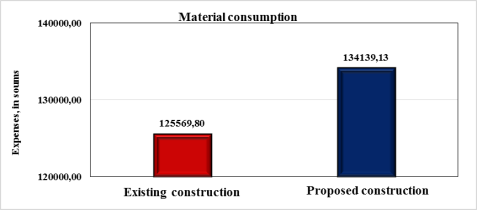

Fig. 3.Consumable costs for materials

Fig. 3 is a graph of material costs for the structures, where we can see that the existing style is 7 % cheaper than the proposed style.

The total cost of constructions per 1 m 2 is given in table 4.

Table 4

|

Existing construction |

Proposed construction | ||

|

Transportation |

5 % |

6,278 |

6,707 |

|

Transportation |

2 % |

2,511 |

2,683 |

|

Total material |

134,360 |

143,529 | |

|

Total direct costs |

150,281 |

148,530 | |

|

Other contractor costs |

24 % |

35,451 |

35,038 |

|

Total |

185,733 |

183,568 |

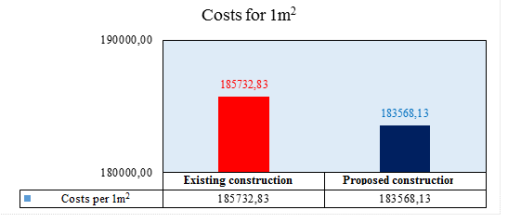

Fig. 4. Costs for 1 m 2

From the graphs in Fig. 4, we can see that the total cost of the existing structure is 2 % higher than the proposed structure.

Taking into account the long service life of basaltofibrobeton, we will consider the economic analysis of the operational indicators of the structure.

Analysis of operational costs

By fully controlling the technology of construction work, using high-quality basalt-fibro concrete, it is possible to achieve the service of the construction of the traffic section built in a monolithic form for more than 30 years without requiring repair work. In this way, it is possible to significantly reduce the operating costs of the facility [1].

The results of the following inspections (observations) are taken into account when determining the operating costs of reinforced concrete bridges and overpasses: current and periodic; inspections and tests; special observation and inspections. The service life of the bridge and the period until the first repair are determined according to the Interstate standard GOST 33178–2014 [4].

According to GOST 33178–2014, the repair period of the waterproofing layer is 10 years, and the replacement period is 20 years. In practice, the repair period is 5 years, and the replacement period is 10 years [5].

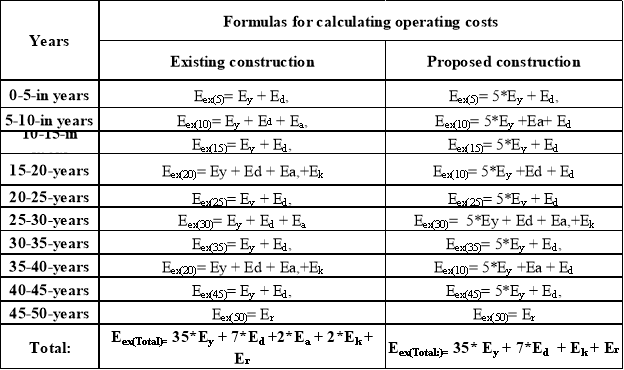

In calculating (forecasting) the cost of operation of bridges and overpasses by year, we will calculate according to the method developed by U. Z. Shermukhamedov and A. B. Karimova [4]. That is, the formulas for calculating expenses for every 5 years are given in Fig. 5.

Fig. 5.

E A = Annual operating expenses;

E D = Costs incurred for replacement of deformation seams;

E A = Costs for replacing asphalt concrete pavement;

E R = Costs for reconstruction.

If we make a theoretical prediction based on this method, the method we propose is partially precast-monolithic, and although the amount of expenses is equal in some 5-year periods, in the total last 50-year period, the capital repair of the bridge and asphalt concrete We can see that the cost of replacing the coating is completely saved.

Although the price of basaltofibro concrete is higher than the price of ordinary concrete, its features such as improvement of operational characteristics, extension of service life, reduction of labor ranks give it an advantage over ordinary concrete.

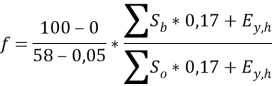

The efficiency of the use of complex modified concrete developed for the carriageway is not high, as can be concluded from the above graphs. Research also shows that when fiber is used in concrete, their long-term performance ensures efficiency. V. P. Based on the conclusion of the church, the service life for reinforced concrete is 58 years, G. M. According to the conclusion of Kondrashov and B. M. Goldshtein, the service life of basaltofibrobeton is 100 years. The replacement period of ordinary reinforced concrete roadway constructions is T=18 years, in this regard, the replacement period of basalt-fibro concrete is T=0.

Here:

t o va t m — appropriate service periods of simple and complex modified concrete;

P o va P m — the probability of occurrence of a state of deterioration in the plate due to the corresponding wear of simple and complex modified concrete;

S b va S o — the amount of costs for simple and complex modified concrete, respectively;

F n — normative coefficient, here it is taken as equal to 0.17;

E y,h — annual operating costs.

The above integral indicator showed f=1.9 when calculated based on today's prices. This allows us to conclude that the long service life of MB and, at the same time, its operation period, when calculated according to the project, completely eliminates the cost difference between the materials used for it and ordinary concrete.

Conclusion.

When comparing the labor costs of workers and machines-mechanisms in the construction of the existing and proposed constructions, it is possible to save 79 % and 90 %, respectively, in the proposed construction.

The cost of fillers and binding materials in complex modified concrete means that the proposed structure does not have great economic savings compared to the existing structure, but the fact that the structure has a long-term service feature can significantly reduce the operating costs of the structure.

By fully controlling the technology of construction work, using high-quality basalt-fibro concrete, it is possible to achieve the service of the construction of the traffic section built in a monolithic form for more than 20 years without requiring repair work. This will significantly reduce the operating costs of the facility [1].

The construction proposed by this work cannot completely eliminate the defects that occur in some traffic sections, however, we believe that it is partially effective, both technically and economically, compared to the old method.

References:

- Malikov G., Urazov K., Gulmatova Z. Technical and economic comparative analysis of the use of modern materials in the traffic section of the reinforced concrete highways bridge // Евразийский журнал академических исследований. — 2023. — Т. 4. — №. 1. — С. 151–157.

- Transport inshootlarining ekspluatatsiyasi, sinovi va reabilitatsiyasi. Ch.S. Raupov. Darslik. «Transport» nashriyoti, T.: 2016.

- Бабаев В. Б. Мелкозернистый цементобетон с использованием базальтового волокна для дорожного строительства //Автореф. Диссертации на соиск. уч. степени канд. техн. наук. — 2013.

- Shermukhamedov U. Z. et al. Comparison of operating costs of reinforced concrete bridges and overpasses with different static schemes //E3S Web of Conferences. — EDP Sciences, 2023. — Т. 401. — С. 02035.

- ГОСТ 33178–2014 Дороги автомобильные общего пользования. Классификация мостов.

- https://mk-monteko.ru/metallokonstruktsii/mostovie-konstruktsii/betonirovanie-proezzhey-chasti-mosta

- https://vekha.ru/fibrobeton-tehniko-ekonomicheskaya

- Негматуллаев С. Х., Оснос С. П. Применение материалов на основе базальтовых волокон в строительстве /Строительные материалы, оборудование, технологии XXI века. — 2015. — №. 5–6. — С. 15–19.