Flooding of the pay zones on the deposit Alibekmola is proposed using two sources of water supply:

artesian water from the Albian-Cenomanian complex;

formation wastewaters.

The main technical requirements on the working agent for flooding are:

retention of stable injectivity of the injection wells;

prevention of complications during operation of the injection wells owing to encrustation of the underground equipment with inorganic salts;

prevention of corrosion wear of the water lines of the reservoir pressure maintenance system and the well equipment;

prevention of vitality of sulfate-reducing bacteria in the bottom-hole zone of the injection wells.

Based on data of the technical requirements, the requirements on quality of treatment of the injection waters are formulated.

Treatment of the injection waters is based on technical solutions ensuring retention of stable injectivity of the injection wells.

The given technical solutions are based on substantiated requirements on quality of the injection water, especially quality of the formation wastewaters relative to admissible content of emulsified crude and mechanical impurities.

Prevention of salt deposits is achieved by selecting the source of water supply. Technical water of the chosen source of the water supply is chemically compatible with the formation waters, for which reason complications in operation of the injection wells from salt deposits are not expected.

Suppression of vitality of sulfate-reducing bacteria, the result of which is the appearance of biogenic hydrogen sulfide in the production wells, is not an important task in equipping the deposit Alibekmola, since the content of hydrogen sulfide in the produced crude significantly exceeds the amount that forms during developing of sulfate reduction.

The requirements on water quality used for flooding are imposed according to a broad spectrum of indices.

The requirements on water quality according to the indices are based on data on the physical and hydrodynamic characteristics of the pay zone. The most important information is information on the lithological characteristics of the pay zones, porosity, permeability and also development of fracturing.

The pay zones (KT-II-1 and KT-II-2) are composed of limestones with interlayers of dolomite, clay, rarely conglomerates. The oil reservoirs are limestones and dolomites.

The limestones are nonuniformly porous, fractured and stylolitized, rarely silicified and dolomitized in individual interlayers.

The cement is contact cement of the pore type represented by fine-crystalline calcite, rarely anhydrite.

Open pores are complicated by leaching out to formation of fine caverns. The pores are often connected by thin channels between forms.

Fracturing is confined to the dense rock interlayers. Open cracks are uneven, often weakly tortuous, enclosing shaped residues, lithogenic with an openness of 5‑30 µm, sometimes complicated by leaching cavities and oriented parallel to the rock bedding or at an angle of about 30°. The horizontal cracks are positioned in interlayers en echelon at a distance of 0.5–5 cm from each other. The walls of the cracks are uneven. Open cracks situated perpendicular to the bedding are rarely encountered.

The dolomites are fine-crystalline, secondary, composed of crystals of rhombohedral and irregular shape, darkened by pelitic material. The porosity is uneven. The shape of the pores is angular, irregular with sometimes rounded corners. The pore size is 0.02–0.35 mm.

Quantitative evaluation of the fracturing parameter showed that the capacity of the fractures is insignificant and amounts to a hundredth to a tenth of a percent. For formation KT-II-1, the openness of the fractures is 15–20 µm, for formation KT-II-2, the openness of the fractures is 5–30 µm.

As mentioned above, fracturing is confined to the consolidated rock interlayers. A porous-fractured type of reservoir is characteristic of these rocks. There are no fractures in the effective interlayers and leaching pores are present in the reservoirs of the pore type. The average permeability for formation KT-1 is 0.0176 µm2, for formation KT-II-1 0.008 µm2, for formation KT-II-2 0.0105 µm2.

Under conditions when the effective thicknesses of the objects are very significant, as is observed in Alibekmola, the errors in determining the permeability coefficient can be very high. Core data apparently give understated permeability values. Although fracturing of the reservoir is relatively limited, the presence of fractures has nevertheless been established and although they are insignificant, they do increase the permeability of the reservoir. An indirect indication of the effect of fractures on the increase in rock permeability of the reservoir are the results of determination of the productive characteristics of the wells, which are relatively high. Thus, the average specific productivity factor was 0.339 for formation KT-1, 0.548 for formation KT-II-1 and 0.261 m3/day·MPa·m for formation KT-II-2. Thus, from the results of investigation of the reservoir properties of the pay zones of the Alibekmola field, the latter are assigned to the porous-fractured type of reservoir rock.

According to RDS 39–01–041–81, the following standard indices are established for this type of reservoir in terms of content:

crude to 15 mg/L;

mechanical impurities to 15 mg/L.

The dispersity of the particles in the injection water should not exceed 10 µm.

In the formation wastewater arriving in the reservoir pressure maintenance system, free hydrocarbon gas should not be present and the oxygen content according to the standard OST 39–225–88 must not exceed 0.5 mg/L.

According to the requirements on the working agent for flooding, the process and the equipment used to accomplish it must ensure production of degassed formation wastewater that is stable in chemical compositions, containing no more than 15 mg/L crude and 15 mg/L mechanical impurities. Moreover, the water after purification and treatment must contain no more than 0.5 mg/L oxygen and have low corrosion activity (less than 0.1 mm/year).

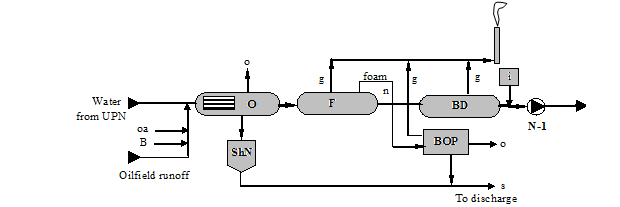

Consider the technological option (Figure 1)that meets the requirements listed above.

Fig. 1. Flow chart of full treatment of wastewater based on equipment from the Реtreco Co: О — ribbed settling tank; F — flotation device; BD — buffer-degasser; N-1 — pump; BOP — foam treatment unit; ShN — sludge accumulator; g — gas; o — crude; s — sludge; i — corrosion inhibitor; k — oxygen absorber; B — bactericide

The formation wastewater from the UPN together with the oilfield runoff, treated with an oxygen absorber and bactericide, goes to the first purification stage, the pressurized settling tank O. Passing through the settling tank, the water is sent to the second purification stage — flotation device F in which turbulent flotation with hydrocarbon gas is carried out.

The purified water passing through the buffer-degasser BD is fed by pump N-1 to the flooding system. The corrosion inhibitor is fed to the intake of pump N-1.

The crude trapped in the settling tank O is returned to the UPN and the mechanical impurities that settle on the bottom of the settling tank (oil sludge) go to the sludge accumulator.

The foam trapped in the flotation device F is withdrawn to the foam treatment unit BOP where it is separated into crude, gas and oil sludge. Gas from the flotation device, the foam treatment unit and the buffer-degasser are flared, the crude from the foam treatment unit are returned to the UPN and the sludge from the sludge accumulator ShN and the foam treatment unit BOP are periodically removed for disposal.

In an installation for purification of formation wastewater according to this option, it is possible to guarantee that the requirements on water quality used in flooding will be achieved.

However, in designing this variant, attention must be focused on the technical solutions for treatment and utilization of the foam sludge.

References:

- Уточненная технологическая схема разработки месторождения Алибекмола. ТОО НИИ «Каспиймунайгаз», ЗАО «КОНКОРД» Договор № 04TD01Ук7–101/ДГРг. Атырау, 2008

- Проект пробной эксплуатации нефтегазового месторождения Алибекмола. Отчет ЗАО «НИПИнефтегаз». Договор 43/2000. Актау, 2001.

- Сазонов Б. Ф. О влиянии совместной разработки продуктивных пластов на эффективность разработки нефтяных залежей на примере Мухановского месторождения. Материалы научно-практической конференции. ЦКР 6–8 апреля 1999 г. Москва, с. 94–100.

- ОСТ 39–228–89 Оценка совместимости закачиваемой воды с пластовой водой и породой продуктивного пласта.

- ТЭО целесообразности разработки нефтяного месторождения Алибекмола республики Казахстан. ВНИИОЭНГ, Москва, март 1996 г.

- Методика определения химической совместимости пластовых вод нефтяных месторождений Волго-Уральского района (для условий сбора, подготовки и утилизации) РД 39–30–1214–84.

- Определение химической совместимости пластовых вод нефтяных месторождений. Методическое руководство. Куйбышев, 2004 г.