Result are brought In work the analysis dug research material on erection monolithic reinforced concrete bent element at construction small floor buildings on the territory of the Republic of Uzbekistan. The Broughted results of the work on provision of toughness, acerbity and rift stability bent element from monolithic reinforced concrete.

They are shown defect and mistakes, allowed when raising bent element from monolithic reinforced concrete, is specified their origin.

In scientific work are stated results executed scientific studies on development practical recommendation on construction bent element from monolithic reinforced concrete.

Keywords: composite reinforcement, polymer, glass fiber, basalt fiber, carbon fiber, aramid fiber.

В работе приведены результаты анализа накопленного научно-технического материала по возведению бетонных конструкций, армированных композитной арматурой при строительстве зданий и сооружений в настоящее время на территории Республики Узбекистан и за рубежом.

В работе приведены виды композитной арматуры, их технология производства, физико-механические свойства различных марок композитной арматуры и сравнение показателей с традиционной стальной арматурой.

Ключевые слова: композитное армирование, полимер, стекловолокно, базальтовое волокно, углеродное волокно, арамидное волокно

The capital construction sector plays an invaluable role in the socio-economic development of any country. During the years of independence, many buildings and structures have been built in our country. These include automobile plants in Samarkand, Tashkent, Asaka, the oil refinery in Karavulbozor, Uzsalaman and Eurasia-TAPOdisk in Fergana, the Museum of the History of the Temurids in Tashkent, the Uzbek State Conservatory complex, the Palace of International Conferences, the Palace of Symposiums. new lines, many banks, bridges, colleges and academic lyceums built in all provinces, hospitals, residential buildings.

In the creation of composite polymer reinforcement (KPA) in the former USSR and the Russian Federation A. A. Gvozdev, K. V. Mixaylov [3], N. A. Moshchanskiy [4], O.Ya. Berg [5], N. P. Frolov [6–8], Vildavskiy Dyugai [9], Aslanova L. G. [10] have been successful in their scientific work.

Similar studies are being conducted in the United States, Germany, France, Canada, Japan, and many other countries.

The authors have developed a technology for the production of glass fittings by pultrusion, studied various polymers for the production of KPA, studied the effects of abrasive environment on glass fibers.

In the Republic of Uzbekistan, the demand for reinforced concrete elements and elements reinforced with composite reinforcement is 0.2–0.8 % of the total polymer composites [2].

Composite polymer fittings (KPA) play an important role in composite materials. KPA is a reinforced rod made of continuous reinforcing roving and thermoactive resin. In foreign literature, the term «Fiber reinforced polymer rebar (FRP-rebar)" can be found.

The creation of the KPA is practically the result of the rapid development of the chemical industry. It is noted that in a number of countries (former USSR, Germany, Japan, USA, Netherlands, etc.) in the 60s of the XX century began research work on the construction of composite polymer fittings.

In the Republic of Uzbekistan, more than 20 patents have been obtained for devices for technical solutions for the use of composite fittings in building structures and elements.

KPA is divided into the following types based on the factors specified in GOST 31938 with respect to the type of filler reinforcing fiber:

– ASK — fiberglass fittings;

– ABK — basalt fiber reinforcement;

– AUK — carbon fiber armature;

– AAK — aramid fiber reinforcement;

– ACK — combined fiber reinforcement.

ACC is included in the standard of our country on the basis of normative documents of foreign countries.

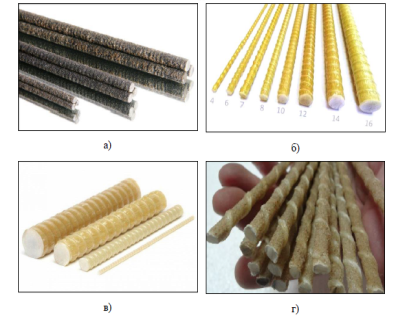

Fig. 1. AKP type armature profiles: a-sand-coated AKP; b-spiral-shaped twisted AKP; The deformation of the v-profile AKP; g-combined profile AKP

Table 1

AKP types of composite indicators of armature

|

T / r |

Indicators |

Value |

|

1 |

Temporary resistance to elongation, In terms of MPa |

Not less than 800 |

|

2 |

Elasticity modulus, GPa |

Not less than 50 |

|

3 |

Relative elongation, % |

2,1–2,3 |

Areas of application of composite reinforcement

Composite fiberglass fittings can be used in buildings and structures designed for various functions, such as steel fittings:

- In industrial and civil construction.

- In concrete structures of residential and other buildings.

- On paving slabs made of light (foam concrete) and heavy concrete, on cast foundations.

- In multi-layer brick piles of brick buildings.

- On the fastening anchors of external thermal insulation on the walls of buildings.

- As rods of reinforcement mesh of building constructions.

- As an inclined binder in three-layer walls of industrial, civil and agricultural buildings (load-bearing layer + coating decorative layer + heater virgin layer).

- In shore protection works.

- In marine and port facilities.

- Rehabilitation of sewerage systems in reclamation networks of water resources.

- The construction of the road surface and barriers.

- Numerous tests have been conducted to study the physical and mechanical properties and corrosion resistance of composite reinforcement, and it has been found that glass reinforcement has many advantages over conventional steel reinforcement.

Technical and economic performance of composite reinforcement

Consumers mistakenly compare a ton of finished product. In fact, due to the large difference in the density of materials, the length of 1 ton of composite reinforcement is on average 5 times longer than that of steel reinforcement of the same diameter.

For example, if the length of 1 ton of composite reinforcement is 20,000 m when the diameter is 6 mm, the length of steel reinforcement of the same diameter is 4,500 m.

Therefore, it would be appropriate to compare the 1 pm length of the product. 1.1 The following table A-III class ASP-type composite reinforced with steel armature to click on the mutual consistency of comparative indicators (cost, weight and length).

Table 2

Comparative table of replacement of A400 armature with ASP armature of equal strength

|

A400 class steel fittings |

ASP type composite fittings | |||||||

|

Markasi |

Weight of 1m, kg |

Length of 1 ton, m |

Market price sum / m |

Equally strong exchange |

Weight of 1m, kg |

Length of 1 ton, m |

Price of 1 m fixture, including VAT (retail) |

1 m ining Price including VAT (wholesale) |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

8A400 |

0.395 |

2530 |

1608.01 |

ASP-6 |

0.05 |

20,000 |

1526.60 |

agreed |

|

10A400 |

0.62 |

1620 |

2558.86 |

ASP-7 |

0.06 |

16650 |

1875.53 |

agreed |

|

12A400 |

0.89 |

1126 |

3678.37 |

ASP-8 |

0.07 |

14280 |

2180.85 |

agreed |

|

14A400 |

1.21 |

826 |

5015.95 |

ASP-10 |

0.12 |

8330 |

3554.96 |

agreed |

|

16A400 |

1.58 |

633 |

6554.18 |

ASP-12 |

0.20 |

5000 |

4507.09 |

agreed |

|

18A400 |

2.00 |

500 |

8214,54 |

ASP-14 |

0.26 |

3840 |

6251.77 |

agreed |

|

20A400 |

2.47 |

405 |

10220.92 |

ASP-16 |

0.35 |

2850 |

8578.01 |

agreed |

Let’s look at these calculations in an example. 40,000 p.m. for a break. if it is used in the steel reinforcing composite with a metal replacement will be necessary. This requires A-III fittings with a diameter of 10 mm. By performing special calculations, we replace the steel reinforcement with composite reinforcement and compare the figures The calculation results are given in Table 2.

Table 3

|

Armature brand, diameter |

Materials |

Strength |

Size, m 3 |

Weight, kg |

Price, so'm |

|

A-III D = 10mm, L = 40000 m |

steel |

Listed in the project on demand |

12.56 |

24800 |

100958816 so'm 2512.33 so'm / pm at the expense of |

|

ASP D = 7mm, L = 40000 m |

composite |

Equally robust |

4.52 |

2400 |

75021240 so'm 1875,53so'm / expense pm |

The calculation shows that when using composite fittings, the cost is reduced by 25.7 %. 25937576 so'm will be saved.

If we pay attention to the table, steel valves for the transport of large cargo capacity, the means of transport is required, due to the low weight of the composite armature load capacity of the vehicle. This in turn economies. The mass of the structure will be reduced to 22,400 kg.

The above comparisons show the advantages of composite reinforcement in many respects.

Conclusion: According to the results of research, the service life of building structures made of composite reinforcement is at least 100 years.

Such long-term durability is explained by the high chemical resistance of composite reinforcement in all types of aggressive environments.

Fiberglass reinforcement is a promising material in the reinforcement of concrete structures, the technical characteristics of which allow you to easily restore the load-bearing and barrier structures:

Using the maximum temperature 60 0 SGA;

Stretching maximum strength of 800 MPa or more of the cross-cut by more than 150MPa and more;

The compressive strength limit is 300 MPa and more; the density of the material is 1.9 t / m 3 ;

The coefficient of thermal conductivity equal to 0.35.

The conducted research and analysis showed that for the widespread introduction of composite fittings in construction practice, it is expedient to conduct experimental and theoretical research in the context of the Republic of Uzbekistan.

References:

- The Constitution of Uzbekistan is a solid foundation for us on the path of democratic development and building a civil society. M. Mirziyoyev's speech at the solemn ceremony dedicated to the 24th anniversary of the adoption of the Constitution of the Republic of Uzbekistan. «Khalq so'zi» newspaper, December 9, 2016.

- Gvozdev A. A. K Voprosova o blijayshix prospects rascheta structures PO predelnym sostoyaniyam. –M.: Stroyizdat, 1981, p. 38 –13. Gvozdev AA, Zaleski AS Osnovnыe napravleniya razvitiya teorii jelezobetona po predelnym sostoyaniyam. Concrete and reinforced concrete, 1980, № 4, p. 14–16.

- Ilin D.A Composite reinforcement on the basis of steel and carbon fiber for concrete construction. Dissertation for the degree of candidate of technical sciences. Moscow 2017 year. (13 pages) 141 pages.

- The luminaire nemetallicheskaya // pod redaktsiey K. V. Mixaylova et al. // Stroyindustriya i promyshlennost: encyclopedia. M.Stroyizdat.1996.

- Solijonov Hojiakbar Solijon o’g’li, S. H. (2021). ANALYSIS OF COMPOSITIVE ARMATURES. EPRA International Journal of Multidisciplinary Research, 7(5), 494–496.