Research purpose is to study physical and chemical properties of ash and slag waste from combustion of Ekibastuz coals and determine possibility of obtaining demanded building materials from them to reduce the burden on the environment.

Keywords: ash and slag ovals, thermal power plant, ecology, secondary resources, building materials.

Целью исследований является изучение физико-химических свойств золошлаковых отходов от сжигания экибастузских углей и определение возможности получения из них востребованных строительных материалов для снижения нагрузки на окружающую среду.

Ключевые слова: золошлаковые отвалы, ТЭЦ, экология, вторичные ресурсы, строительные материалы.

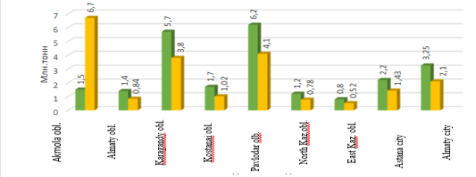

Introduction. Kazakhstan has a significant number of thermal power plants, as a result of which more than 500 million tons of ash and slag waste have been accumulated on the territory of state, reserves of which by 2030 will increase to 1 billion tons. It is known that storage of ash waste is a very costly undertaking. Fuel and electric power complex is one of the main «pollutants» of the natural environment. Deterioration of environmental situation is not unreasonably associated with atmospheric pollution [1]. According to expert estimates, investments in reconstruction of one ash and slag dump can reach 5 billion tenge, and the construction of a new one costs 10–12 billion tenge. Storage of ash and slag wastes leads not only to withdrawal of significant land areas, but also causes very significant pollution of almost all environmental components in the area of their location. Fig. 1 shows volumes of ash and slag waste generation by regions of the republic in 2017–2022. Other regions of Kazakhstan use gas fuel.

Fig. 1. Formation of ash and slag waste in the regions of the Republic of Kazakhstan

Urgency and significance of this problem is intensified with fact that technogenic wastes of CHPP are not recycled, current ash wastes accumulate and occupy vast areas, which takes them out of land use. In the republic, annual output of ash and ash and slag mixtures from coal combustion is about 19 million tons, in ash dumps in 2019 more than 5300 million tons of waste were accumulated (about 8.5 thousand hectares are occupied for storage). (Fig. 2). Development of electricity production and processing of waste from thermal power plants, in particular, ash from coal combustion, are one of the main state priorities of Kazakhstan [2].

Processing of ash and slag waste on industrial scale is practically absent. About 8 % of ash (less than 1.9 million tons) of ash and slag waste from coal produced by thermal power plants is processed in Kazakhstan at research and production level. If use of ASW remains at this level, then by 2030 volume of accumulated waste will reach 1 billion tons.

Today, many foreign countries have experience in the development of efficient environmental and economic systems of non-waste technology. For Kazakhstan, this experience is useful in terms of use in the field of processing and disposal of ash and slag waste. Problem of slag utilization in construction remains urgent task, since almost all research is limited to experimental development. All this causes urgent need for targeted comprehensive studies of both the slag itself and materials based on it. Therefore, waste management has acquired particular relevance today as one of the key areas for the development of the «green» economy in Kazakhstan, i.e. conservation and effective management of ecosystems [3, 4].

Growth in the construction scale in Kazakhstan requires significant amount of minerals for building materials industry. Expansion of mineral resource base of building materials industry can be ensured not only by searching for new deposits of non-metallic minerals, but also by involving non-metallic raw materials in production of technogenic waste. Industrial processing of technogenic raw materials (wastes of enrichment and processing, overburden, and enclosing rocks), close in composition to natural and used in traditional areas, practically does not differ from industrial processing of natural mineral raw materials.

Intensification in this direction is associated with use of industrial waste instead of primary natural resources to reduce cost of building materials. In this direction, employees of KazNITU conduct a large amount of research together with the Central Laboratory for Certification Testing of Building Materials (CLCTBM) and launched a mini-factory for production of secondary raw materials based on production waste [5, 6]. Young scientists and PhD students of Satbayev KazNRTU named after K. I. Satpaevay take active part in these studies (Fig. 2).

Fig. 2. Participation of young scientists in laboratory research

By burning coal, thermal power plants receive thermal energy and generate electricity. Negative side of this process is formation of by-products of coal combustion — fly ash and slag.

Currently in Kazakhstan, aerated concrete with a density of 700, 800 and 900 kg/m 3 of non-autoclave hardening is produced in large quantities — this is the most popular product, especially for civil engineering [7].

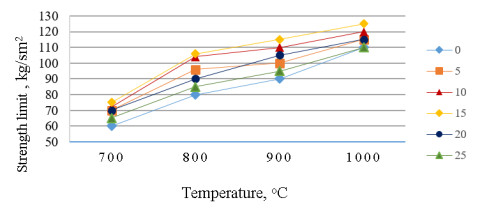

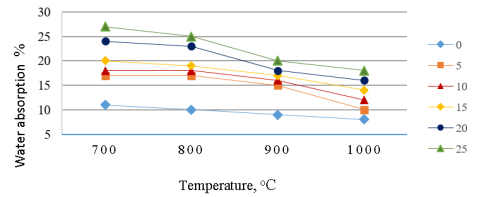

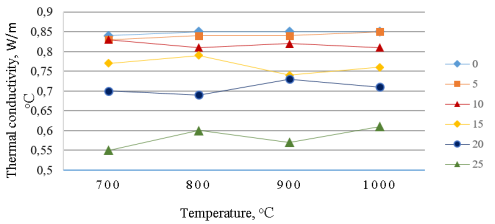

Further work consisted in the manufacture of samples of ceramic bricks with addition of ash and slag waste. In the work, method was chosen for obtaining laboratory ceramic bricks by plastic molding with different percentage of ash and slag waste and annealing at different temperatures. For clarity, all data are summarized in Table. 1. and fig. 4, 5 and 6. Figures show graphs of firing temperature and proportions.

Table 1

Physical and mechanical characteristics of bricks at different percentages of ash and slag waste and different firing temperatures

|

Ash content in clay, % |

Thermal conductivity, W/m ºС |

Water absorption, % |

Strength limit under compression, кg/sm 2 | ||||||||||

|

Temperature, ºС |

Temperature, ºС |

Temperature, ºС | |||||||||||

|

700 |

800 |

900 |

1000 |

700 |

800 |

900 |

1000 |

700 |

800 |

900 |

1000 | ||

|

0 |

0,84 |

0,85 |

0,85 |

0,85 |

11 |

10 |

9 |

8 |

60 |

80 |

90 |

110 | |

|

5 |

0,83 |

0,84 |

0,82 |

0,85 |

17 |

17 |

15 |

10 |

70 |

96 |

100 |

115 | |

|

10 |

0,83 |

0,81 |

0,82 |

0,81 |

18 |

18 |

16 |

12 |

72 |

104 |

110 |

120 | |

|

15 |

0,77 |

0,79 |

0,74 |

0,76 |

20 |

19 |

17 |

14 |

75 |

106 |

115 |

125 | |

|

20 |

0,70 |

0,69 |

0,73 |

0,71 |

24 |

23 |

18 |

16 |

70 |

90 |

105 |

115 | |

|

25 |

0.55 |

0,60 |

0,57 |

0,61 |

27 |

25 |

20 |

18 |

65 |

85 |

95 |

110 | |

Fig. 4. Graph of dependence of tensile strength on firing temperature

Fig. 5. Graph of dependence of water absorption of sample on firing temperature

Fig. 6. Graph of dependence of thermal conductivity of sample on firing temperature

Analysis of studies of ash and slag waste from combustion of Ekibastuz coal showed that thermal conductivity, strength and water absorption depend on amount of added ash and the firing temperature. Greater content of ash in a brick, lower its thermal conductivity. Water absorption increased with increase in ash. Compressive strength also decreases as the ash content of brick increases. Optimal percentage of adding ash and slag waste is 15 percent at a firing temperature of 1000 degrees [8].

Conclusions. Thus, results of conducted studies showed possibility of using ash and slag waste as secondary raw material to obtain building materials and reduce anthropogenic load on environment. Use of ash and slag waste in various construction industries will make it possible not to accumulate ash and slag at ash and slag dumps and affect environment and will reduce use of natural resources.

This study was carried out within framework of grant funding from the Ministry of Science and of Higher Education of the Republic of Kazakhstan BR21882292 — «Integrated development of sustainable construction industries: innovative technologies, production optimization, effective use of resources and creation of technological park»

References:

- Ministry of Energy of the Republic of Kazakhstan. Official Internet resource [Electronic resource] — 2022. — http://energo.gov.kz/index.php?id=2960 (accessed 24.09.2022).

- Current trends in the processing and use of ash and slag waste from thermal power plants and boiler houses [Electronic resource] / G. R. Mingaleeva [and others] // Modern problems of science and education. — 2 014. — No. 6. — Access mode: http://www.scienceeducation.ru — Access date: 29/09/2016.

- Decree of the President of the Republic of Kazakhstan «On the Concept for the transition of the Republic of Kazakhstan to a «green economy»» dated May 30, 2013, No. 577.

- German Federal Ministry for the Environment. Waste Prevention Program. 2013.

- Kuldeyev Е. I., Nurpeisova М.B, Bеk А. А., Аshimova А. А. Waste management is one of the key directions development of «green» economy in Kazakhstan// //М.: Mine Surveyring and Subsurface Use. № 6. 2022. — pp.67–75.

- Patent of the Republic of Kazakhstan for utility model No. 9953 dated 03/06/2023 Method for producing an ash-containing binder (authors: Kuldeev E. I., Nurpeisova M. B., Yestemesov Z. A., Bek A. A., Ashimova A. A.).

- Patent of the Republic of Kazakhstan for a useful model No. 9951 dated 03.03.2023 “Composition of non-autoclaved ash-gas concrete and method for its production (authors: Kuldeev E. I., Nurpeisova M. B., Estemesov Z. A., Ashimova A. A..);

- Bek A. A., Z. А. Yestemesov, Baidzhanov D. O. N. А. Fedotenko. Effective strengthening solutions for fractured rock masses using tailings // «Eurasian Mining» 1–2022. рр.59–64. DOI: 10.17580/еm.2022.12