The article describes one of the stages of the implementation of a computational and experimental methodology for assessing the structural strength of a material using a railway wagon wheel as an example. The author examines the features of numerical simulation of the stress-strain state of a railway car wheel with a pan-head disk shape. The boundary conditions for fixing and loading the wheel correspond to the movement of the car in a curved section of the track. The results of the analysis of finite element modeling of wheel deformation show a sufficiently high level of stress intensity in the rim zone from the outside of the wheel, while the type of stress-strain state is more «rigid» than in the elastic zone, which affects the resource of static and fatigue strength.

Keywords: structural strength, railway car wheel, type of stress-strain state, finite element method.

The design assessment of the reliability of units and parts of equipment can be provided if there is reliable experimental information about the fatigue strength of structural elements. It is essential that the service life of the element depends on the type of stress-strain state (SSS) in the possible focus of its destruction [1], [2], [3]. A characteristic feature of the SSS type of solid-rolled wheels of railway cars is a high level of compressive stresses. During operation, in some cases, fatigue cracks appear, located in the junction zone of massive wheel elements (rim, hub) with its relatively thin disk part (Fig. 1).

Fig. 1. Fatigue cracks in the rim zone of the wheel

The calculated assessment of the service life of the wheels is based on the experimentally determined fatigue characteristics (fatigue curve) of the wheel material, determined under repeated-variable loading of standard laboratory samples for bending. The purpose of this work is to improve the accuracy in determining the fatigue characteristics of the structural material by testing special laboratory samples that allow modeling the required type of stress-strain state in the zone of the structure under study. The calculation and experimental method proposed in this connection [4], [5], [6] allows implementing the mechanism for determining the specified strength characteristics of the structure under consideration, determined by the destruction in laboratory conditions of special samples that have the same type of SSS in the focus of their destruction., as in the focus of possible destruction of the structure under consideration, using a typical single-drive testing machine.

Methodology and results of calculation of the stress-strain state of the object of study

The main contribution to the deformation of the wheel during operation is the weight of the car. For this reason, vertical static forces are considered, which are determined by the permissible axial load on the wheelset of the car. For the completeness of modeling the loads on the wheel, the horizontal transverse reaction forces for the direction of movement were also taken, which arise in a curved section of the track, typical for the Irkutsk railway range. For definiteness, a wheel corresponding to GOST 10791–2011 is considered (see Appendix A, Fig. A.1 GOST 10791–2011). The geometric model of the wheel was developed on the basis of the dimensions of the wheel profile with a flat-conical disk shape. The wheel is a body of revolution, but has a complex axial section profile. For this reason, its geometric model was created in a CAD program and then imported in the form of a solid model in the form of a universal data exchange file in the Parasolid format into a finite element (FE) analysis program (Fig. 2).

Fig. 2. Geometric model of the wheel according to GOST 10791–2011

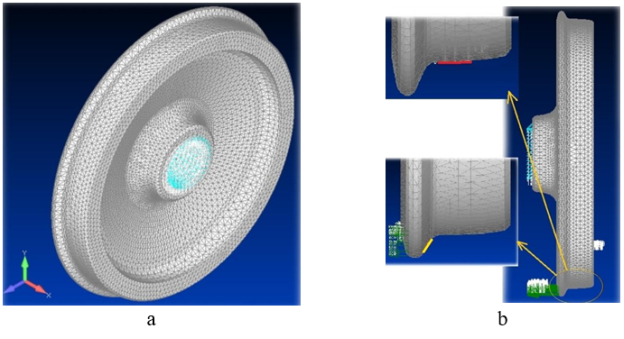

Fig. 3. Discrete wheel model according to GOST 10791–2011

The analysis of the SSS type of the considered wheel according to GOST 10791–2011 was carried out numerically by using the equations of elasticity theory, the solution of which was determined using the finite element method (FEM) implemented in the Femap with NX NASTRAN software package. To create a three-dimensional finite element model of the wheel, a markup was previously created with the parameters of the FE mesh necessary to achieve acceptable engineering accuracy in calculating the criterial characteristics, primarily the stress intensity in the centers of possible destruction. Discretization of the wheel model was carried out according to the method [7], while providing the necessary accuracy — the relative error in modeling the maximum equivalent stresses did not exceed 5 %. The material parameters for the finite element model of the wheel were assumed to be close in properties to the mechanical characteristics of wheel steel Grade 2 according to GOST 10791–2011. In this case, the following values of physical characteristics were taken into account in the calculation: modulus of elasticity (E) — 2.06 ·105 MPa; shear modulus (G) — 0.79 ·105 MPa; transverse deformation coefficient (n u ) — 0.3; linear expansion coefficient (a) — 0.12 ·10–4 °C -1; density (r) — 7850 kg/m 3 . The three-dimensional finite element model of the wheel is shown in fig. 3.

Fig. 4. Boundary conditions for calculating the SSS of a solid-rolled wheel:

a — conditions of fixing; b — loading conditions

Boundary conditions for fastening were imposed on the inner surface of the wheel hub. Restrictions are imposed on the degrees of freedom in the coordinate directions of the used Cartesian coordinate system. The width of the zone of fastening of the hub surface of the axle corresponded to the size of the wheel hub in the longitudinal direction for the axle under consideration (Fig. 4a). As loads on the wheel, we took the horizontal transverse forces for the direction of movement of the reaction forces arising in a curved section of the track, schematically shown in Fig. 4b. These forces are applied to the inner surface of the wheel flange in its lower part (see the yellow line in the projection in the side view of Fig. 4b). A vertical static force is applied to the wheel tread (see the red line in the projection in the side view of Fig. 4b), which is determined by the allowable axial load on the car wheelset [8], [9]. The accepted values of loads on the wheel are applied in the form of forces determined by the formulas of the probabilistic method for calculating the strength of the wheelset axle [10]. The results of the analysis of the finite element modeling of the deformation of the wheel from the design load are shown in fig. 5 as a distribution of equivalent stress fields.

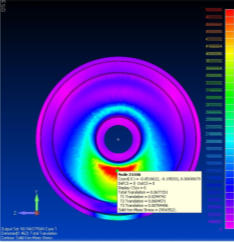

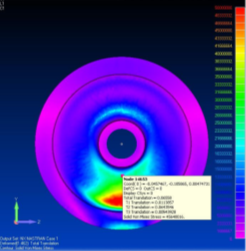

Fig. 5. SSS results of a solid wheel — outer side

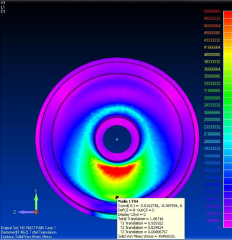

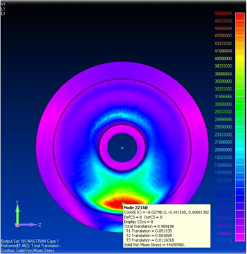

Fig. 6. SSS results of a solid wheel — inner side

It should be noted that the maximum intensity of equivalent stresses (for the wheel as a whole) is located in the rim zone from the outside (in the zone of formation of ring cracks during operation). It turned out that in the considered case, the type of SSS, characterized by the coefficient П, equal to the ratio of the first invariant of the stress tensor to the second one [11], is equal to П = –0.7. In turn, in the rim zone on the inner surface of the wheel, the level of stress intensity is 30 MPa lower (Fig. 6). In this case, the calculated value of P in this zone has a value equal to P = -0.9. In the parietal zone on the outer surface (Fig. 5) and in the rim zone on the inner side (Fig. 6) of the wheel, the type of SSS is approximately the same and is characterized by a P value equal to P = -1.2. The value of the coefficient P is an invariant characteristic of the type of SSS — its larger values correspond (according to the terminology of G. A. Smirnov-Alyaev [11]) to a more “hard” type of SSS, and its smaller values correspond to a “softer” type of SSS. In addition to physical invariance, a feature and, at the same time, an advantage of the P criterion is its dependence on all three principal stresses in the site of possible failure. According to the works [3], [11], [12], the parameter P significantly affects the appearance and development of defects in the material of structures, and with a decrease in the value of P under conditions of cyclic loading, the plasticity and the resource of cyclic work of the material of the structure increase. The obtained values of P show that in the rim zone (Fig. 5) the type of SSS is more “hard” [12] than in the rim zone, and the fatigue life of the material, as shown by the experience of operating the wheels of the considered type (see Fig. 1), is more short.

Study of the structural strength of the material of the object of study

In accordance with the implementation of the calculation and experimental methodology [4], [5], [6] to determine the values of the strength characteristics of the wheel material at the identified values of the coefficient P, it is necessary to select the appropriate experimental laboratory samples so that their SSS type coincides with the SSS design type, whose material strength is estimated. A series of disk laboratory samples [13] was made in the amount of three pieces. Their dimensions were chosen so that in their working area the type of SSS was characterized by a value of P close to P = –0.7, which is typical of the SSS of the wheel zone, where ring cracks form during operation. The material of the experimental samples was selected close to the properties of steel used in the manufacture of solid-rolled railway wheels. Such a material, close in its physical and mechanical characteristics to wheel steel, was steel grade 50 XFA. A preliminary tensile test was carried out on standard round specimens made of 50 XFA steel. The results showed that the selected steel is characterized by the values of yield strength σ t = 1050 MPa, ultimate strength σ v = 1300 MPa and relative elongation δ = 7.5 %. Experimental destruction of disk samples was carried out on a typical Instron 5989 single-drive testing machine. It showed that the forces at the moment of destruction (the moment a crack appeared in the working zone of the samples) corresponded to a force of 65.5 ± 1 kN (according to the results of averaging the experimental data for three destroyed samples). The obtained value of the force is used as the initial value for the numerical analysis of the stress-strain state of the structural version of the sample by the FEM at the moment of its destruction. In this case, pre-developed computational deformation models were used, confirmed by computational tests. The equations of plastic flow with isotropic hardening (Prandtl-Reuss equations) are used as a mathematical model of the process of development of elastoplastic deformations.

Conclusion

Theoretical studies were carried out using the FEM SSS of the wheel of a railway car with a flat-conical disk shape when the car moves in a curved section of the track. The analysis of finite element modeling showed that in the rim zone the type of SSS is significantly more “rigid” than in the rim zone, which affects the resource of static and fatigue strength, it becomes lower. The development of a calculation method for assessing the static and fatigue strength of parts characterized, like the wheel of a railway car, by a relatively mild type of SSS, requires the development of criteria for their structural strength, depending on the value of the SSS type (coefficient P). At the same time, the reliability and accuracy of these criteria can be assessed based on the use of special laboratory samples that allow modeling the required type of SSS, similar to the type that occurs in the material of the structure being evaluated.

References:

- Писаренко Г. С. Справочник по сопротивлению материалов / Г. С. Писаренко, А. П. Яковлев, В. В. Матвеев. — Киев: Изд-во Дельта, 2008.– 816 с.

- Лебедев А. А. Механические свойства конструкционных материалов при сложном напряженном состоянии / А. А. Лебедев, Б. И. Ковальчук [и др.]. — Киев: Изд-во Дом «Ин Юре», 2003. — 540 с.

- Когаев В. П. Расчеты деталей машин и конструкций на прочность и долговечность / В. П. Когаев, Н. А. Махутов, А. П. Гусенков. — М.: Машиностроение, 1985. — 224 с.

- Зеньков Е. В. Уточнение уравнений предельного состояния материала конструкций с учетом реального вида их деформирования / Е. В. Зеньков, Л. Б. Цвик // Системы. Методы. Технологии. — 2017. — № 2. — С. 28–34.

- Курбонназар С., Ядгор Р., Рустам Р. и Рустам Ю. Л. (2022). Метод анализа для оценки прочности колес грузовых вагонов. Конференция, 171–182.

- Рузметов, Я. О., & Рахимов, Р. В. (2019). Перспективы развития вагоностроения в Республике Узбекистан. In Проблемы и перспективы развития вагоностроения (pp. 147–150).

- Зеньков Е. В. Дискретное моделирование напряженно-деформированного состояния плоскоцилиндрических образцов с концентраторами напряжений в виде канавок / Е. В. Зеньков, Л. Б. Цвик, А. А. Пыхалов // Вестник ИрГТУ. — 2011. — № 7(54). — С. 6–12.

- ГОСТ 33783–2016 Колесные пары железнодорожного подвижного состава. Методы определения показателей прочности. — М.: Стандартинформ, 2016. — 61 с.

- Цвик Л. Б. Вычислительная механика деформирования деталей вагонов: монография / Л. Б. Цвик, Е. В. Зеньков, И. С. Бочаров. — Иркутск: ИрГУПС, 2020. — 164 с.

- Рахимов, Р. В., & Рузметов, Я. О. (2019). Assessment of the impact of the rolling stock with increased axial loads on a way and setting the conditions of their circulation on the railways of the Republic of Uzbekistan. Железнодорожный транспорт: актуальные задачи и инновации, 1(1), 5–13.

- Смирнов-Аляев Г. А. Механические основы пластической обработки металлов. Инженерные методы / Г. А. Смирнов-Аляев. — Л.: Машиностроение, 1968. — 272 с.

- Абдувахобов, М. Э., & Хамидов, О. Р. (2022). Forecasting the Residual Life of the Main Frame and Fitting the Electric Locomotive Into the Curve by the Method of a Parabolic Diagram. International Journal of Formal Education, 1(10), 148–153.

- Ozodovich, R. Y., & Salim o‘g‘li, S. Q. (2021). G ‘ildirakga ta’sir etuvchi vertikal va gorizontal kuchlarning Solidworks dasturida tahlili. Barqarorlik va yetakchi tadqiqotlar onlayn ilmiy jurnali, 1(6), 670–674.