In the article, in order to select a rational option for organizing shunting work at intermediate stations, two options were compared: 1st option: maintenance of intermediate stations by combined trains with work at all stations of the section and with the performance of shunting work by a train locomotive; option 2: maintenance of intermediate stations by a combined train with work at base stations and shunting work by a train locomotive in combination with shunting locomotives. On the example of the A-P section with 11 intermediate stations, the efficiency of the second option for servicing local work is shown.

Keywords: shunting locomotive, railway locomotive, shunting work, intermediate station, support station.

В статье для выбора рационального варианта организации маневровой работы на промежуточных станциях сравнивались два варианта: 1 вариант: обслуживание промежуточных станций сборными поездами с работой на всех станциях участка и с выполнением маневровой работы поездным локомотивом; 2 вариант: обслуживание промежуточных станций сборным поездом с работой на опорных станциях и выполнением маневровой работы поездным локомотивом в сочетание с маневровыми локомотивами. На примере участка А-П с 11 промежуточными станциями показана эффективность второго варианта обслуживания местной работы.

Ключевые слова: маневровый локомотив, железнодорожный локомотив, маневровая работа, промежуточная станция, опорная станция.

INTRODUCTION

The decrease in the volume of local work leads to a sharp decrease in the number of shunting locomotives and locomotive crews. Then it is necessary to assign shunting locomotives to several stations, i.e. the area of operation of each of them expanded, large losses of time occur in the transfer of shunting locomotives from station to station, the need to prepare cars for the move, the hostility of train routes and shunting movements, the inability to send a local train at the right time.

In railway transport, the locomotive economy makes up the bulk of operating costs. In the joint-stock company “Uzbekiston temir yullari” (JSC “UTI”), 35 % of the total operating costs are for locomotive depots, 12 % for fuel and 30 % for electricity [1]. In JSC Russian Railways, this figure was 30 % [2] The positive change in this indicator in JSC «UTI» was achieved mainly due to the introduction of new resource-efficient equipment and technologies.

The lack of shunting locomotives and maintenance personnel at the stations, low speeds during maneuvers with the emerging trend of increasing the volume of freight and train work, poor coordination of their work on the part of the operational personnel of the railway and reference stations became the main reason for the delay in cargo and long idle cars.

According to the analysis of the operation of the stations, the lack of shunting locomotives significantly affected the downtime from the end of cargo operations to departure, which negatively affects the delivery time of the cargo. All this required a comprehensive solution to the issue of optimizing shunting services at the site assigned to the reference station, linking the operation of shunting locomotives with the local train schedule. In connection with the above, a method is proposed for a rational option for organizing shunting work at intermediate stations while ensuring 100 % reliability of processing the local car traffic, taking into account its fluctuations and meeting the specified standards of car downtime.

LITERATURE ANALYSIS AND METHODS

To date, several studies have been carried out to speed up the work of railway stations and optimize fuel consumption [3–18]. However, scientific research on the choice of the optimal variant of traction engines serving intermediate stations has not been carried out enough. The article compares two options to select a rational option for organizing shunting work at intermediate stations:

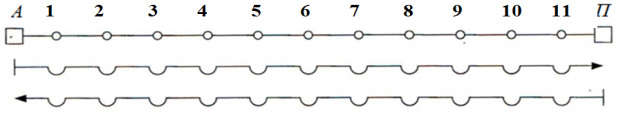

Option 1: maintenance of intermediate stations by combined trains with work at all stations of the section and with the performance of shunting work by a train locomotive (Fig. 1).

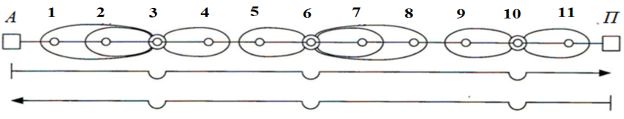

Option 2: maintenance of intermediate stations by a combined train with work at base stations and shunting work by a train locomotive in combination with shunting locomotives (Fig. 2).

Fig. 1. Scheme of servicing intermediate stations by a combined train on the A-P section (option 1)

Fig. 2. Scheme of servicing intermediate stations by a combined train on the A-P section (option 2)

The duration of shunting work with a combined (export) train depends on the locomotive that performs the maneuvers, the place where the wagons are uncoupled from the train, and also on the type of operations performed. The time for these operations is determined based on the rational organization of shunting work.

In the first option, the time for uncoupling and hitching cars at the station by a train locomotive is determined by the formula [19].

T comb (exp) =10,15+0,33∙ m rea +0,29∙ m unc +0,21∙ m att , min. (1)

где m rea — average number of rearranged wagons;

m unc — the average number of wagons uncoupling from the combined train;

m att — average number of trailer wagons attached to a combined train.

In the second option, the time for uncoupling and hitching cars at the station by a shunting locomotive is determined by the formula [19]

T comb (exp) =5,95+0,46∙ m unc +0,16∙ m att , min(2)

RESULTS AND DISCUSSION

The total time for uncoupling and hitching cars at the station by a train locomotive in an even direction is 191.70 minutes or 3.19 hours. To simplify the calculations, we assume that the total time of the odd and even directions are equal. Then the total time for uncoupling and hitching cars for both directions is 6,38 hours.

Since the uncoupling and hitching of cars at intermediate stations is carried out by train locomotives, it is necessary to determine the locomotive and car-hours of idle time along the entire route of combined trains. Calculations for the even direction are carried out in tabular form (Table 1). According to the expenditure rate for 2021, the expenditure rate for one carriage-hour of downtime was 527 soums, the expenditure rate for one locomotive-hours of downtime was 82743 soums and the expenditure rate for one brigade-hours of downtime was 156725 soums. Consequently, the total cost rate for one locomotive and brigade-hours of downtime will be 239468 soums. Then the cost of idle car-hours will be 2824*527=1488248 UZS and the cost of locomotive and crew-hours of idle time will be 6.85*239468=1640356 UZS. Then, the cost of train-hours will be 1488248+1640356=3128604 sum.

Since, in the first variant, the uncoupling and hitching of cars at intermediate stations is carried out by train locomotives, it is also necessary to take into account fuel costs for traction of trains on hauls and arrangement of cars at stations. The total operating time of the train locomotive in the first variant is 6.85 hours. Fuel consumption for one hour of operation of the 2TE10L locomotive in the traction mode is 12 kg/minute or 720 kg/hour. Since, the cost of diesel fuel in 2020 amounted to 3200 sum/kg. Then the fuel costs will be 6.85 * 720 * 3200 = 15782400 sum.

In option 1, the total expenses for the even direction will be 3128604+15782400=18911004 soums, for both directions — 37822008 soums.

The total time for uncoupling and hitching cars at the station by a train locomotive in an even direction is 128.85 minutes or 2.15 hours. To simplify the calculations, we assume that the total time of the odd and even directions are equal. Then the total time for uncoupling and hitching cars for both directions is 4.3 hours.

Table 1

|

Station number |

Number of wagons in combined trains, vag. |

Time for hitching and uncoupling of wagons, hour |

Distillation travel time, min |

Distillation travel time, hour |

Total train running time |

Car-idle hours |

|

1 |

50 |

0.30 |

18 |

0.3 |

0.6 |

27 |

|

2 |

55 |

0.30 |

19 |

0.32 |

1.22 |

61 |

|

3 |

55 |

0.30 |

15 |

0.25 |

1.77 |

97 |

|

4 |

55 |

0.30 |

16 |

0.27 |

2.34 |

129 |

|

5 |

60 |

0.30 |

22 |

0.37 |

3.01 |

166 |

|

6 |

60 |

0.30 |

19 |

0.32 |

3.63 |

218 |

|

7 |

60 |

0.30 |

17 |

0.28 |

4.21 |

253 |

|

8 |

60 |

0.30 |

20 |

0.33 |

4.84 |

290 |

|

9 |

61 |

0.30 |

17 |

0.28 |

5.42 |

325 |

|

10 |

63 |

0.30 |

15 |

0.25 |

5.97 |

364 |

|

11 |

70 |

0.30 |

18 |

0.3 |

6.57 |

414 |

|

-- |

-- |

-- |

17 |

0.28 |

6.85 |

480 |

|

Total |

2824 | |||||

Since the uncoupling and hitching of wagons at intermediate stations is carried out by a shunting locomotive, it is necessary to determine the locomotive and wagon hours of idle train locomotives along the entire route of combined trains and the operation of shunting locomotives at intermediate stations. Calculations for the even direction are carried out in tabular form (Table 2). According to the cost rate for 2021, the cost rate for one carriage-hour of downtime was 527 soums, the cost rate for one locomotive-hour of downtime was 82,743 soums, and the cost rate for one crew-hour of downtime was 156,725 soums. Consequently, the total cost rate for one locomotive and brigade-hours of downtime will be 239468 soums. Then the cost of idle car-hours will be 2201 ∙ 527 = 1159927 soums and the costs of locomotive and brigade-hours of idleness will be 5,70 ∙239468 = 1364967 soums. Then,

Since, in the second variant, the uncoupling and hitching of wagons at intermediate stations is carried out by shunting locomotives, it is necessary to separately take into account the fuel costs for train traction and shunting operations. In the second variant, the operating time of a train locomotive is divided into two components: traction mode and idle mode (parking time). The total operating time of the train locomotive in the traction mode in the second variant is 3.55 hours. The fuel consumption for one hour of operation of the 2TE10L locomotive in the traction mode is 12 kg/minute or 720 kg/hour. Since, the cost of diesel fuel in 2020 amounted to 3200 sum/kg. Then the fuel costs in the traction mode will be 3.55 * 720 * 3200 = 8179200 soums. The total operating time of the train locomotive in idle mode in the second variant is 2.15 hours. Fuel consumption for one hour of operation of the 2TE10L locomotive in idle mode is 0.19 kg/minute or 11.4 kg/hour. Then the fuel costs in idle mode will be 11.4 * 2.15 * 3200 = 78432 soums.

Table 2

|

Station number |

Number of wagons in combined trains, vag. |

Time for hitching and uncoupling of wagons, hour |

Distillation travel time, min |

Distillation travel time, hour |

Total train running time |

Car-idle hours |

|

1 |

50 |

0.20 |

18 |

0.30 |

0.5 |

35 |

|

2 |

55 |

0.20 |

19 |

0.32 |

1.02 |

64 |

|

3 |

55 |

0.20 |

15 |

0.25 |

1.47 |

90 |

|

4 |

55 |

0.19 |

16 |

0.27 |

1.93 |

116 |

|

5 |

60 |

0.18 |

22 |

0.37 |

2.48 |

149 |

|

6 |

60 |

0.19 |

19 |

0.32 |

2.99 |

179 |

|

7 |

60 |

0.19 |

17 |

0.28 |

3.46 |

208 |

|

8 |

60 |

0.20 |

20 |

0.33 |

3.99 |

219 |

|

9 |

61 |

0.20 |

17 |

0.28 |

4.47 |

246 |

|

10 |

63 |

0.20 |

15 |

0.25 |

4.92 |

271 |

|

11 |

70 |

0.20 |

18 |

0.30 |

5.42 |

271 |

|

-- |

-- |

-- |

17 |

0.28 |

5.70 |

353 |

|

Total |

2201 | |||||

In addition, this option takes into account the cost of fuel for shunting operations. Fuel consumption for one hour of operation of the TEM-2 shunting locomotive is 15 kg/hour. Then the fuel costs for shunting locomotives at the stations will be 2.15*15*3200=103200 UZS. Since not all stations have their own locomotives, it is necessary to take into account the fuel costs for the mileage of shunting locomotives between attached stations. It is conditionally accepted that shunting locomotives are attached at three stations in the A-P section — 3, 6 and 10 (Fig. 2). These three shunting locomotives spend 2.32 hours per run. Then the fuel costs for shunting locomotives on hauls will be 2.32*15*3200=111200 soums.

The second option requires 3 locomotive crews. According to the expenditure rate for 2020, the expenditure rate for one brigade-hour of work of locomotive brigades amounted to 156,725 sum/hour. Consequently, the cost of brigade-hours of work of locomotive crews of all shunting locomotives will be 12*3*156725=5642100 soums.

In the 2nd option, the total expenses for the even direction will be 2524894+8179200+78432+103200+111200+5642100=16639026 soums, for both directions -33278052 soums.

CONCLUSION

In the section under consideration, the second option for serving local work with shunting means will save costs in the amount of 4,543,956 soums per day than the first option (37,822,008–33278052 = 4,543,956 soums), and for the year this amount will be 1,658.5 million soums. The cost of one used shunting locomotive of the TEM-2 series as of May 30, 2021 is 701.5 million soums, and three 2104.5 million soums. The payback period of the proposed option is 2104.5/1658.5=1.27 year or 1 year 3 months.

The proposed methodology for choosing a rational option for organizing shunting work at intermediate stations makes it possible to reduce the operating costs associated with the commissioning of a shunting locomotive by reducing inter-operational downtime of wagons and reducing cases of delay in the delivery of goods.

References:

- Бабахалов Н. Э., Гуламов А. А. Экономика предприятий железнодорожного транспорта: учебое пособие. — T.: Fan va texnologiy», 2016. — 140 с.

- Валеев Н. А. Управление затратами в локомотивном комплексе железнодорожной компании: Дисс. к.э.н. 08.00.05. — М.: МГУПС. — 2016. — 132 с.

- Suyunbayev, S. M., & Butunov, D. B. (2019). Development of classification of the reasons of losses in the work sorting stations. Journal of Tashkent Institute of Railway Engineers, 15(2), 167–175.

- Khudayberganov, S. K., & Suyunbayev, S. M. (2019). Results of application of the methods “Sologub” and combinator sorting in the process of forming multi-group trains at the sorting station. Journal of Tashkent Institute of Railway Engineers, 15(4), 62–72.

- Суюнбаев, Ш. М., Жумаев, Ш. Б., & Ахмедова, М. Д. (2020). Процесс расформирования и формирования многогруппного поезда на железных дорогах АО «Узбекистан темир йуллари». Транспорт шёлкового пути, (3), 30–38.

- Khudayberganov, S. K., Suyunbayev, S. M., Bashirova, A. M., & Jumayev, S. B. (2020). Results of application of the methods “Conditional group sorting” and “Combinatorial sorting” duringthe multi-group trains formation. Journal of Tashkent Institute of Railway Engineers, 16(1), 89–95.

- Суюнбаев, Ш. М., & Саъдуллаев, Б. А. У. (2020). Формирование многогруппных составов на двустороннем сортировочном устройстве. Universum: технические науки, (9–2 (78)).

- Кудрявцев, В. А., & Суюнбаев, Ш. М. (2010). Целесообразность использования твердого графика движения грузовых поездов. Сб. ст. ВТИ, (18), 145–149.

- Суюнбаев, Ш. М., & Саъдуллаев, Б. А. (2020). Выбор рационального варианта организации маневровой работы на cтанции. In Приоритетные направления инновационной деятельности в промышленности (pp. 183–186).

- Rasulov, M. X., Masharipov, M. N., Rasulmuhamedov, M. M., & Suyunbaev Sh, M. (2019). The provision terms of train with locomotives and their standing time. International Journal of Advanced Research in Science, Engineering and Technology, 6(9), 10963–10974.

- Masharipov, M. N., Rasulov, M. K., Rasulmukhammedov, M. M., & Suyunbaev, S. M. (2019). Raschet ekspluatiruemogo parka gruzovykh lokomotivov grafoanaliticheskim metodom na yazyke programmirovaniya C#. Intellectual Technologies on Transport, 17, 5–12.

- Kuanyshbayev, Z. M., Suyunbayev, S. M., & Masharipov, M. N. (2013). A study of locomotive components in intermodal and unimodal transportation. Science and world, 49.

- Rasulov, M. X., Suyunbayev, S. M., & Masharipov, M. N. (2020). Research of development prospects of transportation hub in JSC» UMC». Journal of Tashkent Institute of Railway Engineers, 16(3), 71–77.

- Aripov, N. M., & Vladimirovich, R. A. (2021). Rapid planning of mixed-structure train organization in the context of non-proportional wagon-flows. International Journal of Discoveries and Innovations in Applied Sciences, 1(5), 324–335.

- Suyunbayev, S. M., Akhmedova, M. D., Sadullaev, B. A. U., & Nazirov, N. N. U. (2021). Method for choosing a rational type of shunting locomotive at sorting station. Scientific progress, 2(8), 786–792.

- Mukaramovich, A. N., Mansuraliyevich, S. S., & Yakubbaevich, N. D. (2021). Manyovr ishlarida tortuv hisoblarini bajarish uchun poyezdning natur varag ‘i asosida vagonlarning harakatiga o ‘rtacha og ‘irlikdagi solishtirma qarshilikni hisoblash usulini avtomatlashtirish. Oriental renaissance: Innovative, educational, natural and social sciences, 1(10), 50–59.

- Бутунов, Д. Б., Суюнбаев, Ш. М., & Ахмедова, М. Д. (2021). Особенности построения стохастической модели оценки параметра непроизводительного потеря. Academic research in educational sciences, 2(11), 348–362.

- Жумаев, Ш. Б., Суюнбаев, Ш. М., & Ахмедова, М. Д. (2019). Влияние расписания грузовых поездов по отправлению в условиях твердого графика движения на показатели составообразования. Наука и инновационные технологии, (11), 25–29.

- Нормы времени на маневровые работы, выполняемые на железнодорожных станциях ОАО «РЖД», нормативы численности бригад маневровых локомотивов. М. ОАО «РЖД», 2006. — 102 с.