The article presents the results of the research of hybrid cars faults in Primorskiy Region. The research was carried out according to the data provided by the three enterprises in Vladivostok engaged in repair, maintenance and diagnostics of hybrid vehicles: «DV — Avtoelectronika» Co. LTD, «Forsazh» Co. LTD, «Tesla-service» Co. LTD. The study was conducted in order to identify the main causes of failures of hybrid vehicles in the region. The study includes: processing of initial data on the studied cars for the period from 2015 to 2017. The conducted research allowed to determine systems and components that malfunction the most common cause of the failure of hybrid cars, which gave the opportunity to develop recommendations to reduce failures in the operation of hybrid vehicles.

Keywords: hybrid, vehicle, fault, failure, malfunction

Today vehicles must comply meet ecological requirements. Because of emissions of reduction and fuel efficiency hybrid vehicles are of great interest. The operating conditions are not the most favorable in Russia. Vehicles should operate for six months at low temperatures in large areas of country. Decreasing of environment temperature from +25 to -7 leads to reduction of distance on 9 % and increase of energy consumption on 10 %. Road surface also strongly affects the energy consumption and the distance travelled by the vehicle as well [1, 2].

The modern level of automotive industry of the countries — the leaders in the automotive industry, allows to produce cars of high operational reliability. However, the risk of failure of a hybrid car with an increase in mileage and lifetime, increases several times, that in turn can lead to road of accidents increase, reducing environmental safety and other negative consequences.

In this regard, the purpose of this work is to investigate the main reasons for the failure of hybrid vehicles during their operation in Russian conditions [3].

The studies are based on the data provided by three enterprises of the Vladivostok city: Co. LTD “FE–Autoelectronics”, Co. LTD “Forsage”, Co. LTD “Tesla–Service”. All the enterprises render services to the population in hybrid vehicles repair, maintenance and diagnostics. The database included 2.786 cases of applications of hybrid vehicles’ owners to the car service, in the period from 2015 to 2017.

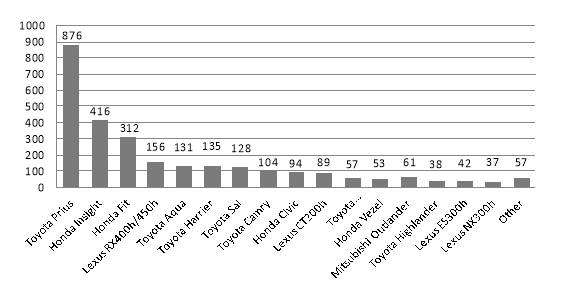

At the first stage, the task was to study the hybrid cars brands received by the car service company. For this purpose, the entire data package was divided into 17 groups, to according the car brands. Then, the total number of applications for each car brand and the applications of the total number of percentage were calculated. The data is shown in the diagram (Fig. 1).

Fig. 1. Number of hybrid vehicles owners of applications to the service

It turned out that 31 % of applications refer to Toyota Prius brand hybrid cars. In general, 57.5 % of applications refer to the cars of three brands: Toyota Prius, Honda Insight, Honda Fit. First of all, this is due to the fact that these brands occupy the leading positions in the secondary auto market and are the most common among city owners. Studies have shown that the remaining brands of hybrid cars presented today in the city account for less than 5 % of applications.

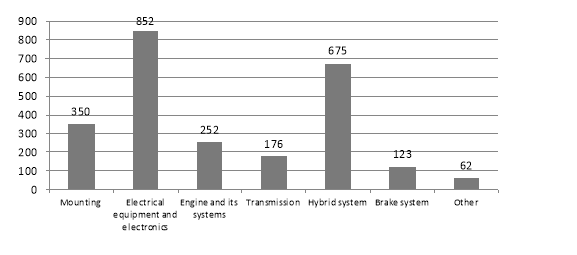

At the second stage of the study, the main failures (malfunctions) of hybrid cars were determined. For this purpose all the applications were divided into 6 groups, according to the main failure (Fig. 2).

Fig. 2. The main types of faults in hybrid vehicles

After the calculation of the failures’ percentage, it turned out that the largest number refers to electrical equipment and electronics (34.2 %). The hybrid system the failure rate from the total number of faults is 27 %. The proportion of suspension is 14 %. The failures of the remaining nodes do not exceed 10 %.

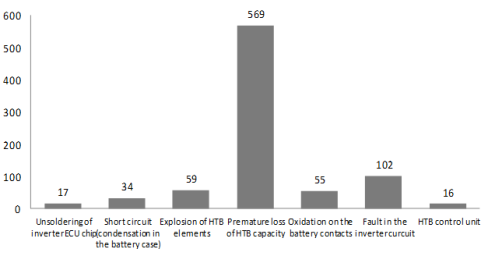

The main types of hybrid vehicles faults distinguish two subgroups of faults: electrical equipment and electronics, a hybrid system. Next, it was necessary to identify the failure of each group. Figure 3 shows a diagram of the main faults of electrical equipment and electronics of hybrid vehicles.

Fig. 3. The main faults of hybrid vehicle of electrical equipment and electronics

It can be seen from the diagram that the main reason for the applications of the owners is the premature loss of the high-tension battery capacity. This failure accounts for 67 % of the total number of applications connected with the electrical equipment faults.

In the assembly of battery in the factory, the elements selected as close as possible to each other are set in it. But over time, their imbalance in capacity, internal resistance and many other parameters take place, which reduce the efficiency of the battery as a whole. Copper contact plates oxidation in a high-tension battery occurs [4]. The vehicle reacts to the quality degradation of the high-tension battery like: increase of fuel consumption, incorrect indication of the level of charge and discharge of the battery, warning signaling and power drop in general [5]. If you continue to ride on such a battery, the risk of explosion of the defective component increases that can lead to ignition the vehicle.

HTB repair is performed to equalizing the individual bundles parameters of battery elements, and to bring its capacity to factory values. In this case, the battery itself is disassembled into separate elements, being tested on a special stand. After the discard of weak cells, the replacement and control-training cycles (equalization) is performed are carried out, the purpose of which is to equalize the capacity of individual pairs of battery elements under a certain load [6].

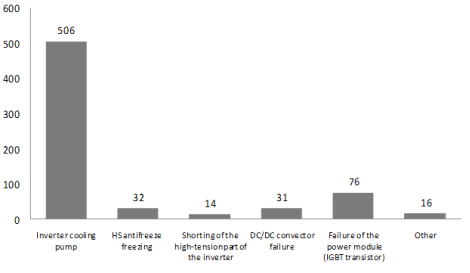

As it was mentioned above, the second type of the most common faults in hybrid cars is associated with a hybrid system (HS). The numerical relationship of the faults of this group is shown in Figure 4.

Analysis of the data showed that the main cause of HS faults is the pump failure of the inverter cooling system. This fault accounts for more than 70 % of failure cases. The share of the remaining failures in the total number of failures of the hybrid system is insignificant (less than 5 %). The only exception is the power module malfunction. This failure occurs in 11.3 % of cases.

Fig. 4. The main faults of the vehicles HS

In a hybrid vehicle there are two cooling systems. The first, as in common vehicles has the following contour: an internal-combustion engine / interior heater / radiator. The second system cools the hybrid part, namely the powertrain with electric motors and the inverter. The fluid in the hybrid circuit is circulated due to electric pump [7]. Two cooling circuits operate autonomously and have their own cooling fluid volume and, respectively, two expansion tanks with liquid level control. The circulation loss in the hybrid circuit (pump’s stopping down, the circuit airlocking) causes the inverter overheating with the subsequent failure. The inverter converts the direct current from the traction battery into an alternating current to supply an alternating current to the traction motor. It is necessary to take rigorous care of the cooling fluid level, its freezing temperature, and also the cleanliness of the hybrid system cooling radiator [8].

Thus, as a result of the study, the following conclusions were drawn:

Firstly, the hybrid car reliability decrease of dependence on its lifetime and mileage was established.

Secondly, the main reasons for failures (malfunctions) of hybrid cars are: a) loss of a high-voltage battery capacity; b) failure of the pump of a cooling system inverter.

Thirdly, in order to reduce the risk of failures (malfunctions) of a hybrid car, the following recommendations are proposed:

Carry out regular battery testing in order to extend its lifetime and avoid its premature replacement.

Avoid the battery overheating and equalize the battery components twice a year, after one hundred and fifty thousand kilometers of mileage. The driver must remember that a high-voltage battery requires constant ventilation system maintenance.

Monitor the cooling liquid level and to replace it in a timely manner.

Do not allow the car operation when the cooling liquid freezes during the cold season.

Replace the inverter cooling pump every one hundred and fifty thousand kilometers of mileage. Remember that the cooling system pump requires a seasonal maintenance.

References:

- S. Chiuta and E. Blom, «Techno-economic evaluation of a nuclear-assisted coal-to-liquid facility», Progress in Nuclear Energy, vol. 54, pp. 68–74, 2012.

- X. Ou, X. Yan, and X. Zhang, «Using coal for transportation in China: Life cycle GHG of coal-based fuel and electric vehicle, and policy implications», International Journal of Greenhouse Gas Control, vol. 4, pp. 878–887, 2010.

- X. Ou, X. Zhang, and S. Chang, «Scenario analysis on alternative fuel/vehicle for China’s future road transport: Life-cycle energy demand and GHG emissions», Energy Policy, vol. 38, pp. 3943–3956, 2010.

- J. Bernard, M. Hofer, U. Hannesen, A. Toth, A. Tsukada, F. N. Büchi, and P. Dietrich, «Fuel cell/battery passive hybrid power source for electric powertrains», Journal of Power Sources, vol. 196, pp. 5867–5872, 2017..

- C. Sapienza, L. Andaloro, F. V. Matera, G. Dispenza, P. CretI, M. Ferraro, and V. Antonucci, «Batteries analysis for FC-hybrid powertrain optimization», International Journal of Hydrogen Energy, vol. 33, pp. 3230–3234, 2008.

- M. Contestabile, G. J. Offer, R. Slade, F. Jaeger, and M. Thoennes, «Battery electric vehicles, hydrogen fuel cells and biofuels. Which will be the winner?»,Energy & Environmental Science, vol. 4, pp. 3754–3772, 2011.

- Division of Heat & Power Technology, Chalmers, 2012. Design of Industrial Energy Equipment. Course Compendium — Spring 2012, pp. 5–8.

- R. K. Ahluwalia, X. Wang, and A. Rousseau, «Fuel economy of hybrid fuel-cell vehicles», Journal of Power Sources, vol. 152, pp. 233–244, 2015.